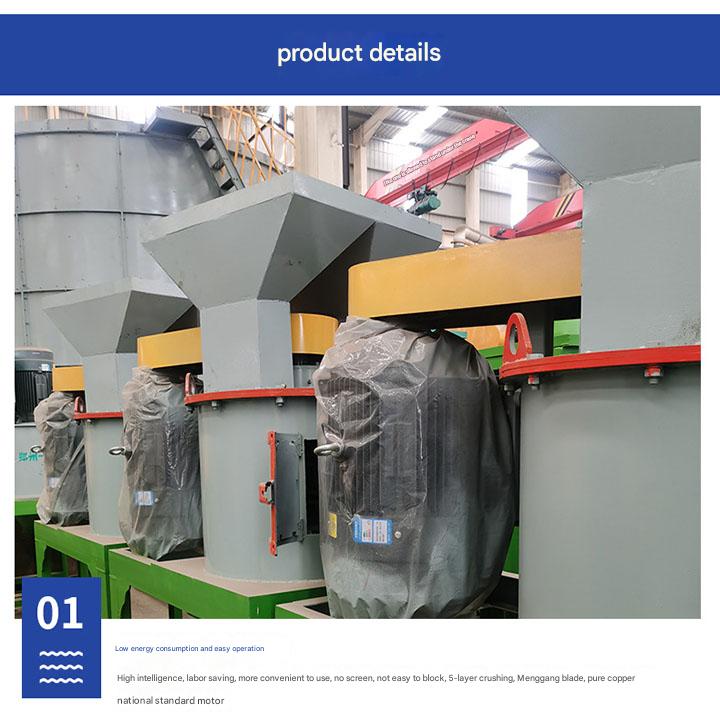

Fully automatic chain crusher equipment

The use of fully automatic chain crusher in the production process of compound fertilizer has the following advantages:

- Efficient crushing: The chain rotor of the fully automatic compound fertilizer chain crusher rotates at high speed, driving the crushing teeth to impact, shear and squeeze the compound fertilizer raw materials, which can quickly crush the materials with high production efficiency and meet the needs of large-scale compound fertilizer production.

- Uniform particle size: By reasonably designing the aperture of the sieve plate and the motion parameters of the chain rotor, the particle size of the crushed compound fertilizer particles can be uniform, which is conducive to subsequent granulation, screening and other processes, and improves the quality stability of compound fertilizer products.

- Strong adaptability: It can adapt to the crushing of a variety of compound fertilizer raw materials, such as various ores, salts, organic materials, etc., and has a good crushing effect on raw materials of different hardness and humidity. It can be flexibly applied when the compound fertilizer production formula is diversified.

- Low wear: The chain structure and crushing tooth design of the equipment make the wear between the material and the components relatively uniform during the crushing process, and the service life of key components is long, which reduces the maintenance cost and downtime of the equipment and ensures the continuity of compound fertilizer production.

- Environmental protection and energy saving: Compared with some other crushers, chain crushers have lower noise during operation, better sealing, and less dust emissions, which is conducive to improving the working environment of the production workshop. At the same time, its efficient crushing method can also reduce energy consumption, meeting the production requirements of environmental protection and energy saving.

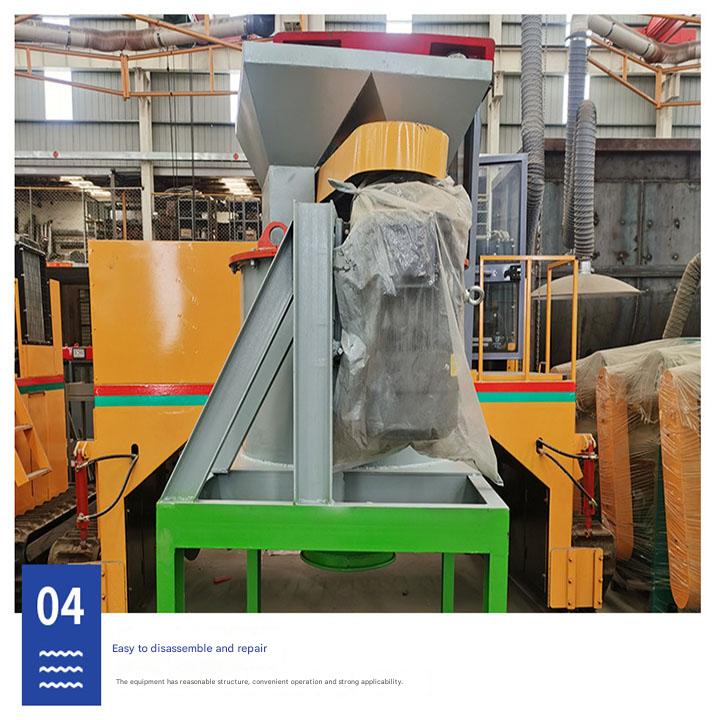

The fully automatic compound fertilizer chain crusher is a kind of equipment commonly used to crush various materials. The following is its relevant introduction:

Structure and working principle

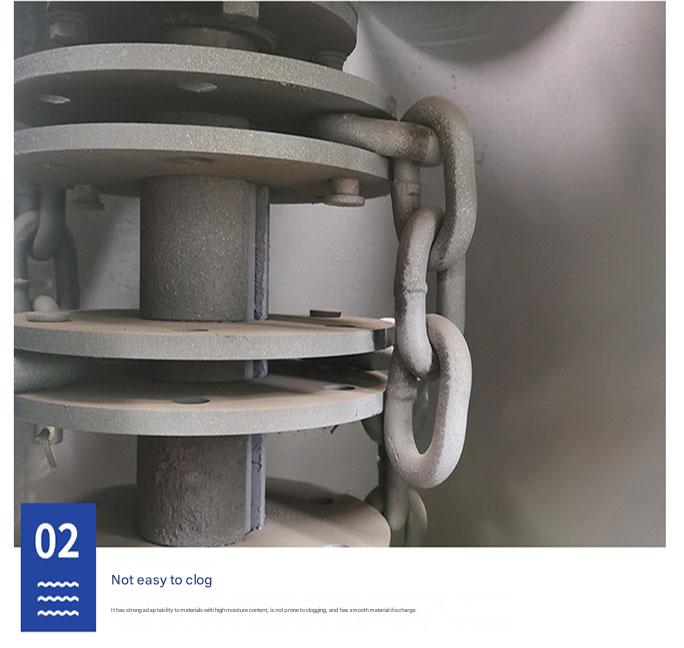

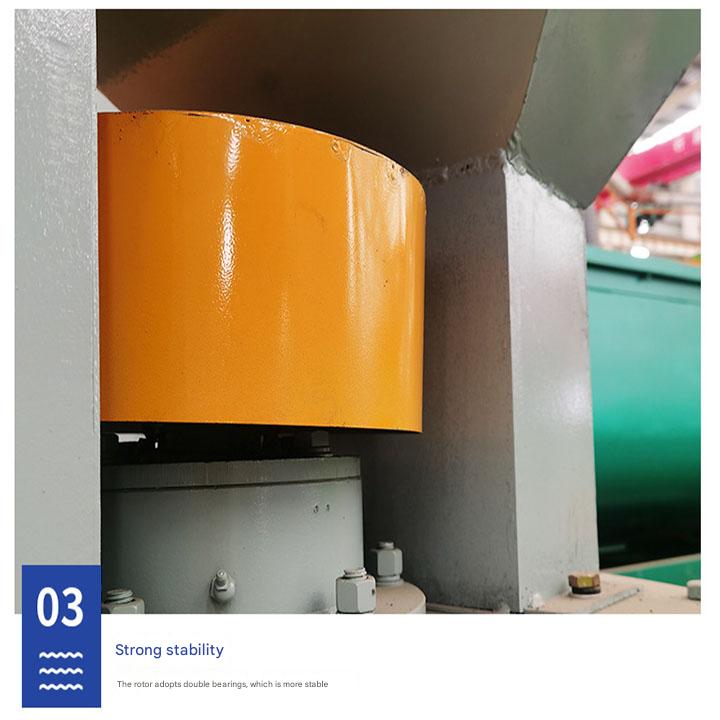

- Structure: It is mainly composed of feed port, crushing chamber, chain rotor, screen plate, discharge port and drive device. The chain rotor is its core component, which consists of multiple chain links and crushing teeth installed on the chain links.

Working principle of fully automatic compound fertilizer chain crusher: the material enters the crushing chamber from the feed port, and the high-speed rotating chain rotor drives the chain links and crushing teeth to impact, shear and squeeze the material to crush it. The crushed material is discharged through the screen plate, and the material that does not meet the particle size requirements continues to be crushed in the crushing chamber until it meets the requirements and passes through the screen plate.

Features of fully automatic compound fertilizer chain crusher

- Large crushing ratio: It can crush materials into smaller particles to meet the needs of different production processes.

- High efficiency and energy saving: The high-speed rotation of the chain rotor makes the crushing efficiency higher, and at the same time, it has lower energy consumption than some other crushers.

- Stable operation: The structural design is reasonable, the equipment has good stability, and can run continuously for a long time.

Strong adaptability: It can be used to crush a variety of materials, such as coal, ore, construction waste, biomass, etc., and has a certain range of adaptability to the humidity and hardness of the materials.

- Low noise and less dust: During operation, compared with some other crushers, the noise is lower, and because the crushing chamber is relatively closed, there is less dust flying, which is conducive to improving the working environment.

The fully automatic compound fertilizer chain crusher is a device that uses high-speed rotating chains to impact and crush material blocks. It is an impact crusher.

Application fields of fully automatic compound fertilizer chain crusher

It is widely used in mining, coal, electricity, building materials, chemical industry, environmental protection and other industries. For example, it is used to crush coal in coal mines; crush various ores in ore processing; crush discarded concrete, bricks, etc. into reusable aggregates in construction waste treatment; and crush straw, branches and other biomass in the field of biomass energy for subsequent processing.

The main working part of the automatic crusher equipment is a rotor with a steel chain, one end of the chain is connected to the rotor, and the other end of the chain is equipped with a chain head made of wear-resistant steel.

The main working part of the fully automatic compound fertilizer chain crusher is a rotor equipped with a steel chain. One end of the chain is connected to the rotor, and the other end is equipped with a chain head made of wear-resistant steel. The chain crusher is an impact crusher that uses the impact of a high-speed rotating chain to break the material blocks.