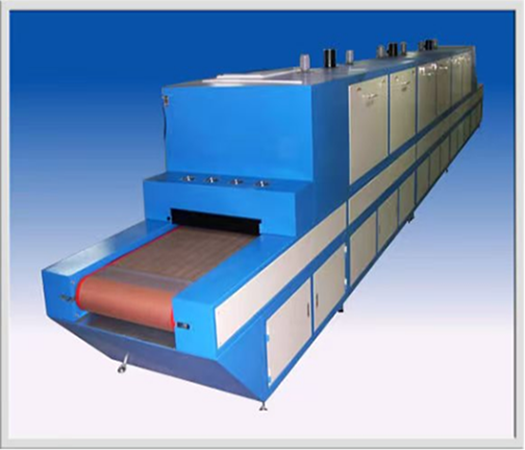

Net belt dryer

Dry evenly

The mesh belt design allows the corn flakes to be evenly spread on the mesh belt, and the hot air can evenly penetrate the material layer, so that all parts of the corn flakes are heated uniformly, thereby ensuring uniform drying and stable product quality.

Continuous production with high efficiency

The corn flake mesh belt dryer can realize continuous feeding and discharging, can run stably for a long time, and is suitable for large-scale production. The running speed of the mesh belt can be adjusted according to the drying requirements of the corn flakes to improve production efficiency.

Strong flexibility

The corn flake mesh belt dryer can flexibly adjust the drying temperature, wind speed, mesh belt running speed and other parameters according to different corn flake varieties, humidity and output requirements to achieve the best drying effect.

Little material damage

The corn flakes are transported smoothly on the mesh belt with less mechanical impact and friction, which can effectively reduce the breakage and damage of the materials and maintain the integrity of the corn flakes.

Easy to clean and maintain

The mesh belt structure of the corn flake mesh belt dryer is simple and easy to disassemble and clean. It can conveniently remove residual materials and impurities during the drying process, reduce the maintenance workload of the equipment, and extend the service life of the equipment.

Environmental protection and energy saving

The high-efficiency hot air circulation system has high heat utilization rate and can effectively reduce energy consumption. At the same time, the waste gas generated during the drying process is discharged after treatment, which meets environmental protection requirements.

Working principle of corn flake mesh belt dryer

The material is evenly spread on the mesh belt by the feeder, and the mesh belt is dragged by the transmission device to move in the dryer. The dryer consists of several units, and each unit has independent hot air circulation. The hot air passes through the mesh belt covered with materials from bottom to top or from top to bottom, completing the heat and mass transfer and taking away the moisture of the materials. The running speed of the mesh belt can be freely adjusted according to the temperature of the material, and the finished products after drying fall into the receiver continuously.

The structure of corn flake mesh belt dryer

- Mesh belt system: Generally, 12-60 mesh stainless steel wire mesh is used, which is resistant to high temperature and corrosion, and can ensure the stability and hygiene of corn flakes during the drying process.

- Heating device: Common heating methods include coal, gas, oil, electric heating or hot air heating to provide heat for the drying process.

- Fan system: including induced draft fan and circulating fan, etc. The induced draft fan is used to discharge the moisture generated during the drying process, and the circulating fan circulates the hot air in the dryer to improve the heat utilization rate.

- Automatic control system: It can realize precise control of parameters such as drying temperature, mesh belt running speed, air volume, etc., to ensure the consistency and stability of drying effect.

Performance parameters of corn flake mesh belt dryer

Take the model S-20HMV as an example, the number of units is 4, the belt width is 500m, the drying section length is 4.6m, the material thickness is 100mm, the operating temperature is 40-150℃, the drying time is 1h, the drying intensity is 18kg water/h, the heat transfer area is 2㎡, and the power is 20kW. The specific parameters of equipment from different manufacturers and models may vary.

Application scope of corn flake mesh belt dryer

It is suitable for drying corn flakes, and can also be used for drying flake, strip, and granular materials with good air permeability, such as Chinese medicinal materials, vegetables, grains, fruits, flowers and leaves, forage, etc.