Fluidized bed cooler

- High cooling efficiency: In the organic fertilizer fluidized bed cooler, the high-temperature organic fertilizer particles are lifted by the upward flowing cold air and are in a suspended state, fully contacting with the cold air, which greatly increases the heat transfer area and heat transfer efficiency, and can quickly reduce the temperature of the organic fertilizer.

- Uniform cooling: Since the material in the organic fertilizer fluidized bed cooler is evenly mixed with the cold air in the fluidized state, each part of the material has the same chance of contact with the cold air, so the cooling effect is uniform, which can effectively avoid local overheating or overcooling and ensure the stability of the quality of the organic fertilizer.

- Strong adaptability: It can adapt to organic fertilizer particles of different particle sizes, shapes and humidity. Whether it is fine powder or larger granular organic fertilizer, it can achieve good fluidization and cooling in the fluidized bed.

- Easy operation: The operating parameters of the equipment, such as air flow and temperature, are easy to adjust and control, and can be flexibly adjusted according to different production needs and material characteristics. It has a high degree of automation, which reduces the complexity of manual operation.

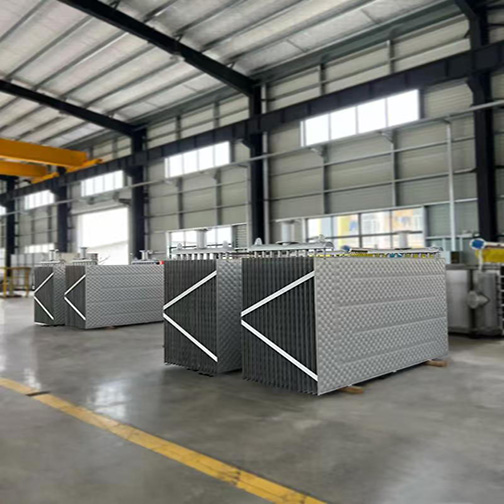

- Small footprint: Compact structure. Under the same production capacity, compared with some traditional cooling equipment, the organic fertilizer fluidized bed cooler has a smaller footprint, which can effectively save production space and improve space utilization.

- Environmental protection and energy saving: The organic fertilizer fluidized bed cooler adopts efficient heat exchange technology, the cold air is fully utilized, and the energy consumption is relatively low. At the same time, the equipment has good sealing, which can reduce dust emissions and meet environmental protection requirements.

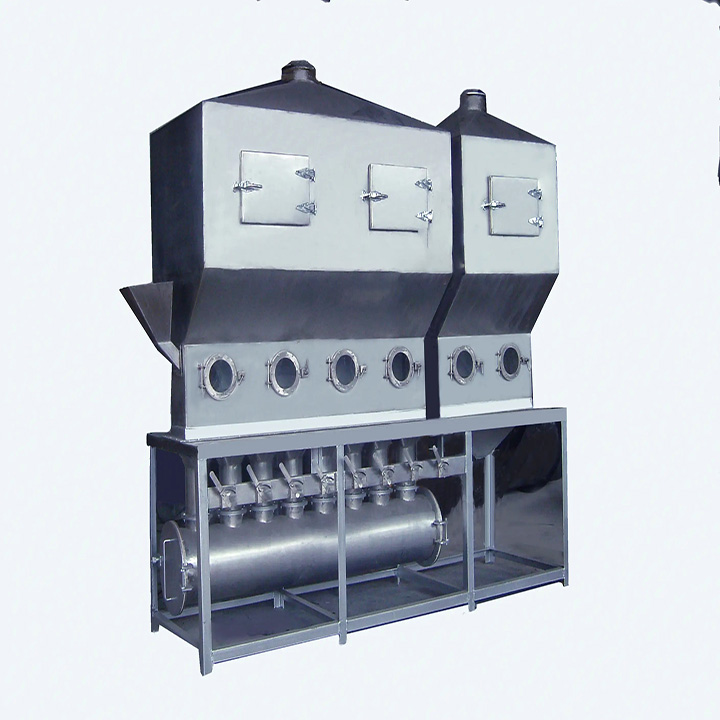

Structural composition of organic fertilizer fluidized bed cooler

- Cooler shell: usually rectangular or cylindrical, it is the main structure of the equipment, used to accommodate materials and cooling media.

- Air flow distribution plate: located at the bottom of the cooler, with many small holes on it, so that the cooling air introduced is evenly distributed, so that the material forms a good fluidized state.

- Cooling water pipe (optional): Some fluidized bed coolers will bury cooling water pipes in the bed, and further absorb the heat of the material through circulating water to enhance the cooling effect.

- The feed port and discharge port of the organic fertilizer fluidized bed cooler are located at the upper and lower parts of the cooler respectively, and are used for the input and output of materials.

- Exhaust port: located at the top of the cooler, used to discharge hot air and a small amount of dust after heat exchange.

- Fan: provides power for cooling air, allowing air to enter the cooler at a certain speed and flow rate.

Performance parameters of organic fertilizer fluidized bed cooler

The performance parameters of different types of organic fertilizer fluidized bed coolers vary. The general processing capacity ranges from several tons to dozens of tons per hour; the material temperature after cooling can be reduced to close to room temperature, usually about 3℃ - 5℃ higher than the ambient temperature; the inlet temperature depends on the actual production situation, generally around 100℃ - 300℃; the power of the equipment varies from a few kilowatts to tens of kilowatts depending on the processing capacity and the configuration of the fan.

Application scope of organic fertilizer fluidized bed cooler

It is mainly suitable for cooling various organic fertilizers, including granular or powdered organic fertilizers made from livestock and poultry manure, straw, etc. Fluidized bed coolers can play a good role, especially for organic fertilizers that need to be cooled quickly to avoid agglomeration, deterioration, or to facilitate subsequent packaging and storage after high-temperature processing such as drying or granulation.