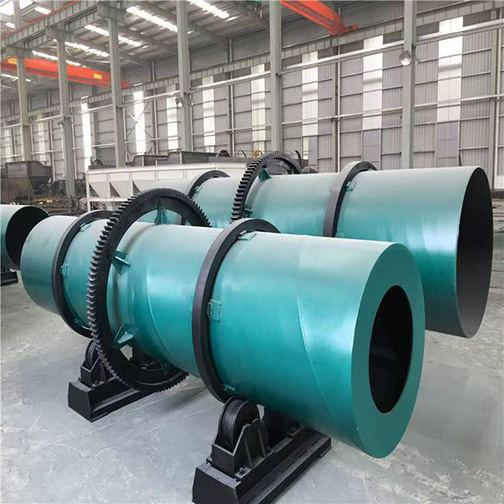

Drum Cooler

The organic fertilizer drum cooler has a good cooling effect: through the rotation of the drum, the organic fertilizer is constantly tumbling in the drum, fully contacting with the cold air to achieve uniform cooling, which can effectively reduce the temperature of the organic fertilizer and ensure product quality.

Simple structure: The organic fertilizer drum cooler is mainly composed of a drum, a feeding and discharging device, a transmission device, etc. It has a compact structure, is easy to operate and has low maintenance costs.

Large processing capacity: The diameter and length of the drum of the organic fertilizer drum cooler can be designed according to production needs. It can adapt to organic fertilizer production of different scales, can operate continuously, and improve production efficiency.

Strong adaptability: The organic fertilizer drum cooler can adapt to the cooling treatment of a variety of organic fertilizers, including organic fertilizers made from livestock and poultry manure, straw, etc., and has good adaptability to the humidity and particle size of the material.

Environmental protection and energy saving: adopting natural air cooling or forced air cooling, the organic fertilizer drum cooler has lower energy consumption than other cooling equipment; at the same time, the waste gas generated during the cooling process is treated and discharged in compliance with the standards, reducing pollution to the environment.

Long service life: The drum is made of high-quality steel, and the organic fertilizer drum cooler is equipped with a wear-resistant lining inside, which can effectively resist the wear and corrosion of the material and extend the service life of the equipment.

High degree of automation: The organic fertilizer drum cooler can be equipped with an automatic control system to realize automatic control of the feeding, cooling, discharging and other processes, reduce manual operations, and improve production stability and reliability.

How it works

The organic fertilizer drum cooler is driven by an electric motor with a pulley, which is then transmitted to the driving shaft through a speed reducer. The split gears on the driving shaft mesh with the large gear ring fixed on the machine body to rotate the drum. The material is added from the feed end. Under the suction of the induced draft fan inside the drum, the air flow in the drum is accelerated. At the same time, the lifting plate on the inner wall of the drum continuously turns up the material, so that it is fully in contact with the cold air, achieving uniform cooling, and the cooled material flows out from the discharge port.

Structural composition

- Drum: It is the main part of the organic fertilizer drum cooler. It is usually made of high-quality steel and has a wear-resistant lining inside to resist the wear and corrosion of the material. The drum is set at an angle, which is conducive to the movement of the material from the feed end to the discharge end under the action of gravity.

- Support mechanism: The organic fertilizer drum cooler includes a support base, a first end cover and a second end cover, etc., which are used to support the drum so that it can rotate stably. The first end cover is set at the lower end of the drum, the second end cover is provided with a feed hopper at the upper position, the first end cover is provided with a discharge hopper at the lower position, and the first end cover is also provided with a vent hole at the upper position.

- Power mechanism: The organic fertilizer drum cooler consists of an outer gear ring fixed on the outer diameter of the drum, a first gear meshing with the outer gear ring, and a power member installed on one side of the first gear, which provides power for the rotation of the drum.

- Cooling mechanism: The organic fertilizer drum cooler includes a stirring assembly and a cooling assembly. The stirring assembly consists of auger plates evenly distributed on the inner wall of the drum, a rotating shaft in the center of the drum, and a diffusion plate on the rotating shaft, which can stir and diffuse the fertilizer; the cooling assembly includes a ventilation ring and a connecting pipe. The ventilation ring is evenly distributed with ventilation holes, and one end is connected to the cold air source through the connecting pipe to cool the fertilizer after stirring.

- Transmission device: The organic fertilizer drum cooler includes a reducer, pulleys, gears, etc., which are used to transmit the power of the motor to the drum so that it rotates at a certain speed and direction.

- Feeding and discharging device: The feeding hopper is located on the second end cover at the high end of the drum, and is used to feed the organic fertilizer material to be cooled into the drum; the discharging hopper is located on the first end cover at the low end of the drum, and is used to discharge the cooled material.

Technical parameters of organic fertilizer drum cooler

- Production capacity: generally 2-50t/h. The production capacity of different types of equipment varies, and can be selected according to actual production needs.

- Barrel size: Common models include LQ12120, with a barrel diameter of 1200mm and a length determined according to actual needs.

- Motor power: Depending on the equipment model and production capacity, the motor power generally ranges from several kilowatts to tens of kilowatts.

Application scope of organic fertilizer drum cooler

It is mainly used in organic fertilizer production lines, compound fertilizer production lines, BB fertilizer production lines, etc. It can cool powdered and granular organic fertilizers made from livestock and poultry manure, straw, urban domestic waste, etc. It can also be used to cool other similar materials.