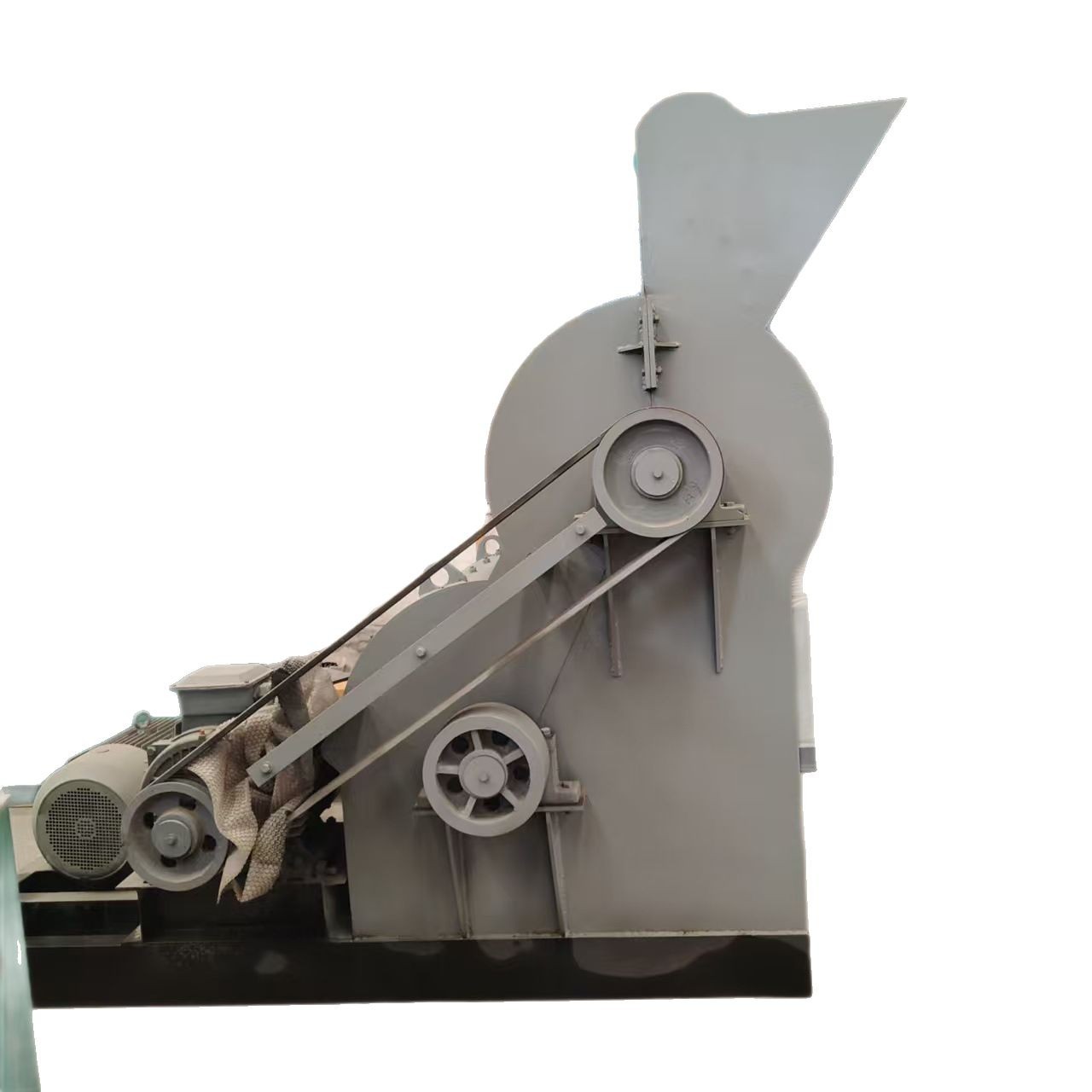

Large bipolar pulverizer

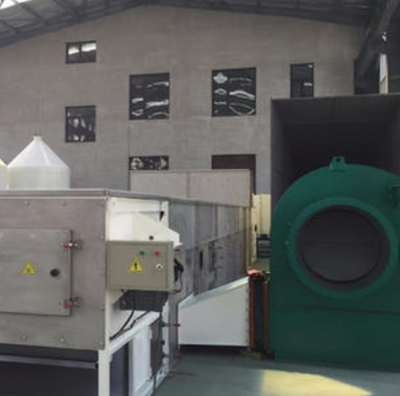

Organic fertilizer double-stage crusher, also known as organic fertilizer double-stage hammer crusher or organic fertilizer double-stage screenless crusher, is an efficient ore and material crushing equipment, especially suitable for fine crushing of medium-hard or brittle materials.

1. Structural features: Organic fertilizer double-stage crusher is equipped with two sets of crushing chambers in series, that is, two independent rotor systems. Each rotor has a high-speed rotating hammer head, which is responsible for impact crushing the materials entering the crushing chamber.

2. Working principle: The raw material enters the crushing chamber from the feed inlet, and a group of hammer heads continuously turns counterclockwise downward to crush the material, achieving the effect of hammering and crushing the material, and then enters the second group of hammer heads for repeated hammering. The two groups of hammer heads hammer and crush the material at high speed. When the material is crushed to a certain fineness, it is discharged from the gap between the hammer heads, thereby ensuring the fineness of the output particle size.

3. Performance advantages of organic fertilizer double-stage crusher

(1) Double rotor upper and lower crusher, good crushing effect, hammer head alloy material, wear-resistant and durable design.

(2) Large crushing ratio, uniform discharge, and high output.

(3) Both dry and wet materials can be crushed, wet and sticky materials can be crushed, and materials with high humidity will not block the machine.

(4) No screen bottom design, suitable for materials with high water content.

(5) Variable speed gap adjustment technology, never block the machine.

(6) One person can open and close, saving labor.

When the organic fertilizer double-stage crusher is working, driven by dual motors, the two sets of rotors connected in series rotate at high speed at the same time. The materials in the machine cavity are crushed by the upper rotor and immediately crushed again by the hammer head of the rapidly rotating lower rotor. The materials in the inner cavity collide with each other and crush each other, achieving the effect of hammer powder and material powder, forming coal slag particles with a discharge size of less than 2 mm.

Organic fertilizer bipolar crusher mainly uses the impact collision principle. The falling materials are impacted by the high-speed rotating hammer head onto the toothed crushing plate. Since the crushing plate is designed with an involute tooth plate, the incident angle of the material colliding with the crushing plate is close to 90°. This vertical collision is a material crushing method that can achieve separation and fine crushing between the grain boundaries of brittle materials.

Since the crushing plate is composed of multiple teeth to form the crushing cavity, the material is impacted by the hammer head and rebounds multiple times in the cavity. When the material falls into the gap between the teeth, it is sized and crushed to control the particle size. The gap between the hammer head and the tip of the crushing plate tooth is 1.5 times the particle size of the discharge. There is no screen plate at the discharge port, so there is no blockage. The material stays in the crushing cavity for a short time. Reduce component wear, low energy consumption and long service life.

Organic fertilizer bipolar crusher has a special structure. A rotor is arranged in the crusher. The hammer is suspended on the disc of the rotor and moves in a high-speed circular motion with the rotor. Organic fertilizer bipolar crusher consists of three parts. The upper cover can be opened. The specially designed toothed crushing plate and the high-speed rotating hammer form a crushing chamber. The feed inlet is located in the middle and at a moderate height. The hammer is connected to the disc through the hammer shaft.

The two ends of the main shaft are supported on the bearings, and the box body is inlaid with a dust-proof disc in the middle of the bearing seat. The bearing is installed on the housing through the bearing seat.

Traditional crushers with grate screen plates are not suitable for raw materials with a moisture content higher than 8. When the moisture content of the raw materials is higher than 10, serious blockage is likely to occur, making the hammer head unable to rotate, the material unable to be discharged, and even burning the motor, seriously affecting production.

The organic fertilizer double-stage crusher is designed without a screen grate bottom, and there is no strict requirement for the moisture content of the material. There is no problem of clogging the screen plate, and there is no problem of fine powder not being discharged in time and repeated crushing. Therefore, the crushing efficiency is high and there is no ineffective wear of the hammer head.

It doesn't matter if the hammer head and liner of the organic fertilizer double-stage crusher are worn out. You can use them repeatedly by just moving the position of the hammer head. One set of hammer heads can replace three sets.