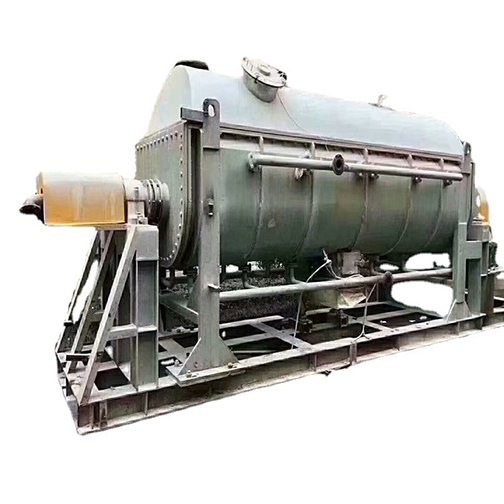

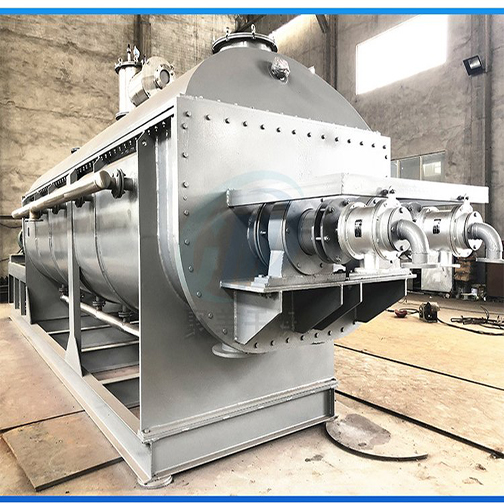

Hollow blade dryer

- High efficiency and energy saving: The paddles of the organic fertilizer hollow paddle dryer are hollow in structure, with heat medium inside, which can directly transfer heat to the material, with high thermal efficiency. At the same time, the equipment adopts low-speed stirring, the material turns evenly during the drying process, the contact area with the paddle is large, the drying speed is fast, and energy consumption can be effectively reduced.

- Organic fertilizer hollow paddle dryer dries evenly: The special design of the paddle makes the material move in a "W" shape in the dryer, avoiding short circuit and bias flow of the material, and ensuring the uniformity of material drying. Moreover, the equipment can adjust the angle, speed and arrangement of the paddle according to different material characteristics and drying requirements to further improve the drying effect.

- Organic fertilizer hollow paddle dryer has strong material adaptability: it is suitable for various types of organic fertilizer materials, including high-humidity and high-viscosity materials. For some difficult-to-dry materials, such as organic fertilizer made from sludge and kitchen waste, the hollow paddle dryer can also effectively dry them through special design and technology.

- Organic fertilizer hollow paddle dryer has good environmental performance: less waste gas is generated during the drying process, and the equipment usually adopts a sealed structure, which reduces the flying and leakage of dust and reduces the pollution to the environment. At the same time, the waste gas can be purified by the matching tail gas treatment device to meet the environmental emission standards.

- Easy operation and maintenance: The equipment has a relatively simple structure, is easy to operate, has a high degree of automation, and can be remotely controlled and monitored. In addition, the organic fertilizer hollow paddle dryer has fewer parts, is easy to maintain, has low maintenance costs, and can reduce the operating costs of the equipment.

How it works

The heat medium is passed into the shell jacket and the hollow blade shaft to indirectly heat the material by conduction heating. At the same time, the blade shaft rotates continuously, pushing the material to move axially and radially in the organic fertilizer hollow blade dryer, so that the material fully contacts the heating surface, thereby achieving drying.

Organic fertilizer hollow paddle dryer structure

It is mainly composed of a "W"-shaped shell with a jacket, a hollow paddle shaft, a transmission device, a sealing device, etc. The "W"-shaped shell can provide a larger material holding space and heating area. The paddles on the hollow paddle shaft are usually wedge-shaped, which can achieve dynamic self-cleaning while stirring the material.

Organic fertilizer hollow blade dryer performance characteristics

- High efficiency and energy saving: Adopting conductive heat exchange technology, the heat transfer area per unit volume is large, the thermal efficiency is high, and only about 1.2kg of steam is needed to evaporate 1kg of water.

- Drying evenly: The stirring action of the hollow paddles causes the material to be constantly turned inside the dryer, fully contacting the heating surface, ensuring even drying of the material.

- Strong material adaptability: It can process organic fertilizer materials in various forms such as paste, granules, powder, slurry, etc., and has good adaptability to materials with different humidity and viscosity.

- Organic fertilizer hollow paddle dryer has good environmental performance: the dust entrainment generated during the drying process is low, the tail gas is easy to handle, and no auxiliary equipment such as dust removal is required. The entire drying process of the material is carried out in a closed state, and organic volatile gases and odorous gases are sent to the tail gas treatment device in a closed atmosphere to avoid environmental pollution.

- Simple operation: The equipment has a relatively simple structure, is easy to operate and maintain, and can accurately control the final moisture content by adjusting the blade speed, material residence time and heat medium temperature.

Technical parameters of organic fertilizer hollow paddle dryer

Taking the KJG series hollow paddle dryer as an example, there are many models such as KJG-3, KJG-9, KJG-13, etc. The paddle shaft speed is generally 1-20rpm, the power is between 2.2-18kW, and the effective volume ranges from 0.06m^{3} to 12.18m^{3}.