Tumble dryer

Large processing capacity: The organic fertilizer drum dryer has a large cylinder diameter and length, which can accommodate a large amount of organic fertilizer materials, realize continuous production, and meet the needs of large-scale organic fertilizer production enterprises.

Good drying effect: the material is continuously lifted by the lifting plate in the drum, fully in contact with the hot air, and heat exchange is carried out, which can make the material evenly heated, the drying effect is good, and the moisture content of the product can reach a low level.

Wide range of applications: Organic fertilizer drum dryer can process various types of organic fertilizer materials, including livestock and poultry manure, sludge, straw, etc., and has relatively low requirements on the particle size and humidity of the materials.

Simple operation: The equipment has a relatively simple structure, stable operation and a high degree of automation. The operator only needs to set the relevant parameters to achieve automatic operation, which reduces the difficulty and labor intensity of manual operation.

Long service life: The main components of the organic fertilizer drum dryer are made of high-quality wear-resistant materials, which have high strength and wear resistance, can withstand long-term high temperature and material wear, and have a long service life.

Environmental protection and energy saving: It adopts advanced hot air circulation system with high thermal efficiency and low energy consumption. It is also equipped with high-efficiency dust removal equipment, which can effectively reduce dust emissions and meet environmental protection requirements.

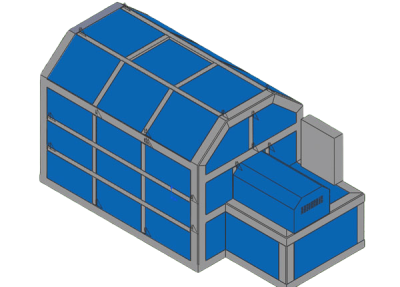

Structural composition

The organic fertilizer drum dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The rotating body is a cylinder slightly inclined to the horizontal direction; the lifting plate is installed on the inner wall of the cylinder, which can pick up and sprinkle the material, so that the contact surface between the material and the airflow is increased; the transmission device is driven by the main motor to drive the belt and pulley, and the transmission is transmitted to the driving shaft through the reducer to make the cylinder rotate; the supporting device adopts a self-aligning tug structure, and the tug and the roller are well matched.

Working principle of organic fertilizer drum dryer

The material is added from the feeding end, and the hot air generated by the hot air furnace enters the cylinder under the suction of the fan. As the cylinder rotates, the material is continuously picked up and sprinkled under the action of gravity and the lifting plate, forming a uniform curtain, which is fully in contact with the hot air for heat exchange, and the moisture contained is gradually dried, and the dried product is discharged from the discharge port.

Technical parameters of organic fertilizer drum dryer

Take the common model as an example, such as HGJ1, the inlet temperature is greater than 300℃, the speed is 6 rpm, the motor power is 10kW, the length is 1200cm, the inclination angle is 3°-5°, and the production capacity is 1-2T/h. Equipment from different manufacturers and models will vary in parameters such as size, power, and production capacity.

Application scope of organic fertilizer drum dryer

It is suitable for processing various organic fertilizer materials such as livestock and poultry manure, sludge, straw, etc., and has relatively low requirements on the particle size and humidity of the materials.

Organic fertilizer drum dryer supporting equipment

It can be matched with hot air furnace, induced draft fan, dust collector, elevator, belt conveyor and other equipment to form a drying production line.