Air flow dryer

Fast drying speed: The organic fertilizer airflow dryer uses high-speed hot air flow to disperse and dry the material in an instant, with high heat transfer efficiency. It can complete the drying process in a short time, greatly improving production efficiency.

High thermal efficiency: The organic fertilizer airflow dryer material is fully in contact with the hot air flow, directly exchanges heat, has small heat loss, and the heat utilization rate can reach 70% - 80%, which is more energy-efficient than some other drying equipment.

Good product quality: Due to the short drying time, the temperature of the material is relatively low during the drying process, and it is not easy to overheat. It can better retain the nutrients and active substances in the organic fertilizer and ensure product quality.

Compact equipment: The organic fertilizer airflow dryer has a relatively simple structure and a small footprint, which can save production space, is easy to install and maintain, and is suitable for organic fertilizer production enterprises of different sizes.

Strong adaptability: It can handle various types of organic fertilizer materials, including powder, granular and fibrous, and has strong adaptability to the initial humidity of the material, which can adapt to different production needs.

Good environmental performance: The organic fertilizer air flow dryer adopts a closed circulation system to reduce the emission of dust and exhaust gas. At the same time, it is equipped with high-efficiency dust removal equipment to further reduce pollution to the environment and meet environmental protection requirements.

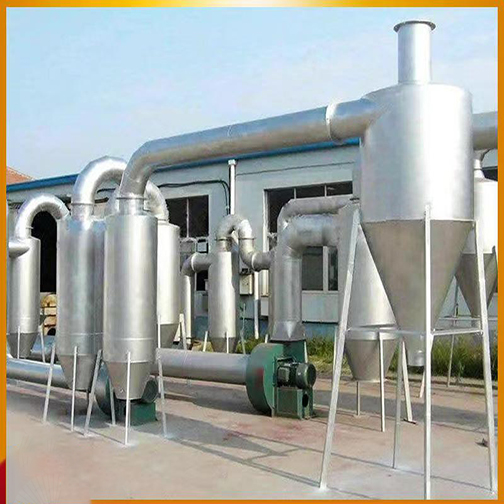

Structural composition

Organic fertilizer air flow dryer usually consists of air heater, feeder, drying tube, cyclone separator, bag dust collector, induced draft fan, etc. The air heater is used to generate hot air flow; the feeder is responsible for evenly adding materials to the drying tube; the drying tube is the main place for heat exchange between materials and hot air flow; the cyclone separator and bag dust collector are used to separate the dried materials and exhaust gas, collect materials and purify exhaust gas; the induced draft fan provides power to make the hot air flow and materials flow in the equipment.

Working principle of organic fertilizer air flow dryer

The wet material is fed into the drying tube evenly by the feeder, and the high-temperature hot air flow generated by the air heater enters the drying tube at high speed. In the drying tube, the material is quickly dispersed and lifted by the hot air flow, forming a suspended state, fully contacting with the hot air flow, and heat exchange is carried out, and the moisture in the material evaporates quickly. The dried material enters the cyclone separator together with the air flow. Due to the centrifugal force, the material is separated and discharged from the bottom, while the exhaust gas containing a small amount of dust enters the bag dust collector for further purification, and finally discharged through the induced draft fan.

Technical parameters of organic fertilizer air flow dryer

Different models of organic fertilizer airflow dryers have different technical parameters. Generally speaking, their processing capacity can range from several hundred kilograms to several tons per hour; the inlet air temperature is usually between 150℃ - 350℃; the air flow velocity in the drying tube is relatively high, generally between 10 - 30m/s; the equipment power varies from tens of kilowatts to hundreds of kilowatts depending on the processing capacity and configuration.

Application scope of organic fertilizer air flow dryer

It is suitable for a variety of organic fertilizer materials, including powder, granular and fibrous materials, such as organic fertilizer raw materials processed from livestock and poultry manure, sludge, straw, etc., especially for materials with high initial humidity.

Organic fertilizer air flow dryer supporting equipment

It is often used together with hot air furnace, feeder, crusher, mixer, granulator, screening machine and other equipment to form a complete organic fertilizer production drying line.