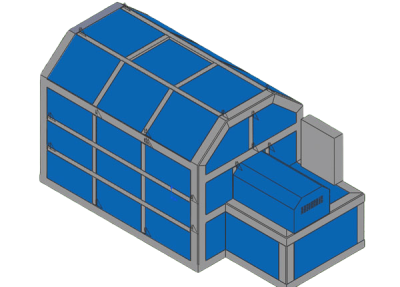

Self-priming fermentation tank

Efficient mixing: The organic fertilizer self-priming fermentation tank uses a special stirring device and self-priming structure to fully mix the material and air in the tank, promote uniform contact between microorganisms and nutrients, accelerate the fermentation reaction speed, and improve the fermentation efficiency.

Good dissolved oxygen effect: The organic fertilizer self-priming fermentation tank can automatically inhale air and disperse it efficiently in the fermentation liquid, increase the solubility of oxygen in the fermentation liquid, provide sufficient oxygen for aerobic microorganisms, which is beneficial to the growth and metabolism of microorganisms, thereby improving the fermentation quality of organic fertilizer.

Energy saving and consumption reduction: Compared with traditional ventilation stirring fermentation tanks, organic fertilizer self-priming fermentation tanks do not require additional ventilation equipment such as air compressors, reducing energy consumption and equipment investment costs. At the same time, its stirring power is relatively low, further reducing energy consumption.

Easy to operate: The structure of the organic fertilizer self-priming fermentation tank is relatively simple, with a high degree of automation and easy control of the operation process. The temperature, pH value, stirring speed and other parameters in the fermentation process can be monitored and adjusted in real time through the control system, reducing manual intervention and labor intensity.

Good sealing: The organic fertilizer self-priming fermentation tank adopts a sealing design, which effectively prevents the contamination of external bacteria, ensures the pure culture of the fermentation process, and improves the quality stability of organic fertilizer. At the same time, it also avoids the leakage of odor generated during the fermentation process and reduces pollution to the environment.

Small footprint: This type of fermentation tank is usually small in size and compact in structure. Under the same fermentation scale, it can make more effective use of space than other large-scale fermentation equipment and is suitable for use in places with limited land resources.

Structural composition of organic fertilizer self-priming fermentation tank

- Tank body: generally made of stainless steel, such as SUS304 or 316L, with good corrosion resistance and sealing properties.

- Self-priming agitator: It is the core component, driven by the main shaft extending upward from the bottom of the tank. When the impeller rotates, the blades displace the surrounding liquid, forming a vacuum on the back and sucking in the air outside the tank through the air duct.

- Organic fertilizer self-priming fermentation tank motor and transmission device: provide power for the agitator so that the agitator can rotate at high speed.

- Cooling device: usually adopts jacket or coil structure, with cooling medium passing through, used to control the temperature during the fermentation process.

- Detection and control system: Equipped with sensors such as temperature, pH value, dissolved oxygen, etc. to monitor fermentation parameters in real time and regulate them through the control system.

- Inlet and outlet: used for adding and discharging materials, usually located at the top and bottom of the tank.

Working principle of organic fertilizer self-priming fermentation tank

When the agitator rotates at high speed, a negative pressure zone is formed in the center of the impeller, which automatically draws in sterile air. The air is broken into small bubbles through the dispersing effect of the impeller and evenly dispersed in the fermentation liquid, achieving efficient gas-liquid mixing and oxygen transfer, and providing sufficient oxygen for the growth and metabolism of microorganisms.

Technical parameters of organic fertilizer self-priming fermentation tank

- Volume: There are many specifications, such as 50L, 100L, 500L, 1000L, etc., which can be selected according to production needs.

- Agitation speed: Generally between 100 - 1000r/min, and the specific speed is adjusted according to the fermentation process and material characteristics.

- Power: Determined by the volume and agitation speed of the fermenter, usually around 0.5 - 10kW.

- Dissolved oxygen coefficient: Under the same air flow conditions, the dissolved oxygen coefficient is higher than that of general fermentation tanks, generally reaching 10 - 50kLa (h⁻¹).

Application range of organic fertilizer self-priming fermentation tank

It is suitable for treating organic wastes such as livestock and poultry manure, kitchen waste, agricultural waste, and producing bio-organic fertilizer, organic compound fertilizer, etc.