Automatic coating machine

The organic fertilizer rotary film coating machine has the following advantages:

- Uniform coating: Through rotation, the organic fertilizer particles can be continuously rolled during the coating process, so that the coating material is evenly wrapped on the surface of the particles, ensuring the coating thickness of each fertilizer is consistent and improving the stability of the coating quality.

- High efficiency and energy saving: The rotary design of the organic fertilizer rotary film coating machine makes the coating process continuous and the production efficiency is high. At the same time, the structure of the equipment is relatively simple, the energy consumption is low, and the production cost can be effectively reduced.

- Strong adaptability: The speed of the coating machine, the supply amount of coating materials and other parameters can be adjusted according to the size, shape and properties of different organic fertilizer particles to meet the coating needs of various types of organic fertilizers.

- Protecting fertilizers: Coating can form a protective film on the surface of organic fertilizer particles, reduce the nutrient loss caused by moisture, oxidation and other factors during storage and transportation, and improve the stability and utilization rate of fertilizers.

- Improve the appearance: Make the surface of organic fertilizer particles smoother and more beautiful, enhance the commodity value of the product, and facilitate market sales.

- Environmental protection and hygiene: The film coating materials of the organic fertilizer rotary film coating machine usually have good environmental performance, and the coating operation is carried out in a closed coating machine, which can reduce dust flying, reduce environmental pollution and improve the working environment.

Organic fertilizer rotary film coating machine is a kind of equipment used for film coating of granular materials. The following is its detailed introduction:

Structural composition of organic fertilizer rotary film coating machine

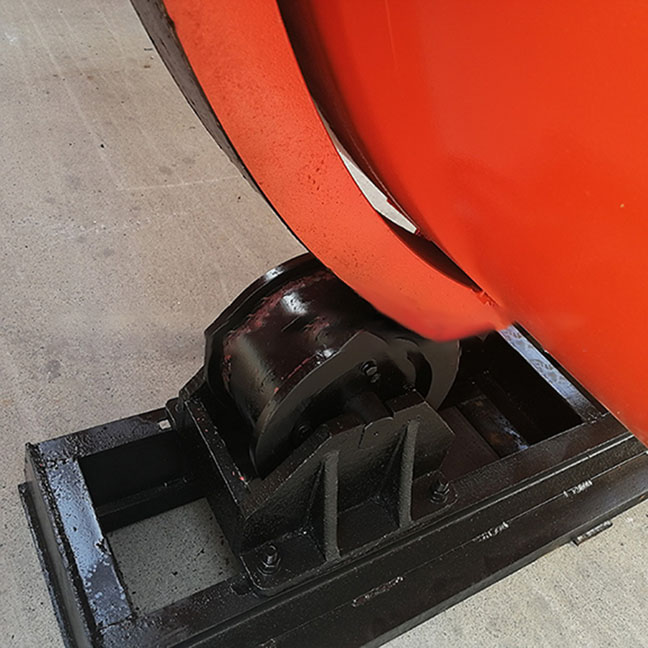

- Drum: It is the core component of the equipment, made of stainless steel, used to load the materials to be coated. The drum is driven by the motor to rotate, so that the materials are constantly rolling in it.

- Spray gun system: Located above or on the side of the drum, it consists of multiple spray guns. The spray gun sprays the configured coating liquid evenly on the surface of the material.

- Liquid supply system: including liquid storage tank, peristaltic pump, etc. The liquid storage tank stores the coating liquid, and the peristaltic pump transports the coating liquid to the spray gun according to the set flow rate.

- Hot air system: It consists of a hot air blower, air duct, etc. The hot air generated by the hot air blower enters the drum through the air duct to dry the coated material and accelerate the curing and film formation of the coating liquid.

- Control system: used to control the speed of the drum, the amount of liquid sprayed by the spray gun, the temperature and flow rate of the hot air, and other parameters to ensure the stability and accuracy of the coating process.

Working principle

When the organic fertilizer rotary film coating machine is working, the drum rotates at a certain speed, so that the material rolls and flows continuously in the drum. The spray gun sprays the coating liquid evenly on the surface of the material, and at the same time, the hot air system introduces hot air into the drum, so that the solvent in the coating liquid evaporates quickly, and the coating material forms a uniform film on the surface of the material. By accurately adjusting each parameter through the control system, accurate control of different materials and different coating requirements can be achieved.

Application field

Organic fertilizer rotary film coating machine is mainly used in pharmaceutical, food, chemical and fertilizer industries. In the pharmaceutical industry, it is used for coating of tablets, pills and other medicines; in the food industry, it is used for coating of candies, nuts, etc.; in the chemical industry, it is used for surface treatment of some granular chemical products; in the fertilizer industry, it is used for coating of granular fertilizers such as organic fertilizers and compound fertilizers.

Maintenance

Clean the equipment regularly to prevent residual materials and coating liquid from drying and clogging the spray gun and pipes. Check the sealing performance of the drum and replace worn seals in time. Regularly inspect and maintain key components such as motors and peristaltic pumps to ensure their normal operation. At the same time, regularly replace wearing parts such as spray gun nozzles and sealing rings according to the frequency of use and condition of the equipment.