Large inclined disc granulator

Compound fertilizer inclined disc granulator is widely used in fertilizer, chemical and other industries, and has the following advantages:

Good granulation effect: Compound fertilizer inclined disc granulator rotates and tilts the disc, so that the material rolls and agglomerates continuously in the disc under the action of gravity, centrifugal force and friction to form regular spherical particles. The particles have high roundness and uniform particle size, which is conducive to improving the quality and market competitiveness of the product.

Adapt to a variety of materials: It can adapt to a variety of materials of different properties. Whether it is a material with high viscosity or a powdery material with good fluidity, the compound fertilizer inclined disc granulator can achieve a good granulation effect. For example, in fertilizer production, the compound fertilizer inclined disc granulator can be used for granulation of various fertilizer raw materials such as urea, ammonium chloride, and monoammonium phosphate.

Easy operation and maintenance: The equipment structure is relatively simple and easy to operate. The operator can master the operation skills after simple training. At the same time, the maintenance of the equipment is also relatively convenient. Daily maintenance mainly focuses on the inspection and lubrication of the disc, transmission parts, etc., thereby reducing maintenance costs and downtime.

High production efficiency: The compound fertilizer inclined disc granulator can achieve continuous production. By adjusting the parameters such as the disc speed, inclination, and feed amount, it can meet the production needs of different scales and has a large production capacity. In addition, the equipment operates stably and has a low failure rate, which can ensure long-term stable operation and improve production efficiency.

Adjustable particle strength: By adjusting the granulation process parameters such as the disc speed, inclination, and material moisture content, the particle strength can be controlled to meet different usage requirements. For example, for granular products that require long-distance transportation and storage, the particle strength can be appropriately increased to reduce crushing and pulverization during transportation.

Good environmental performance: During the operation of the compound fertilizer inclined disc granulator, the amount of dust generated is relatively small, and the equipment can usually be equipped with corresponding dust removal devices to further reduce dust emissions and reduce pollution to the environment. At the same time, the noise level of the equipment is low and will not cause too much noise interference to the surrounding environment.

Structural composition

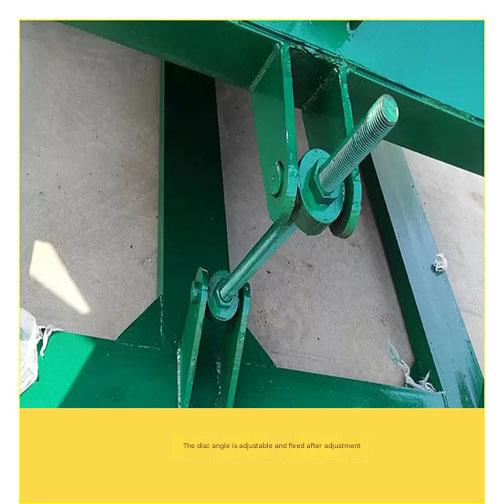

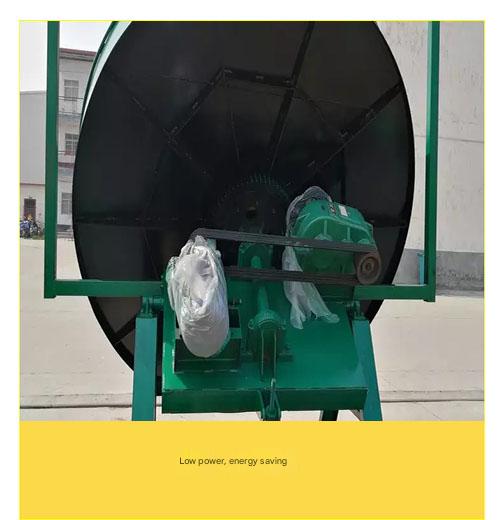

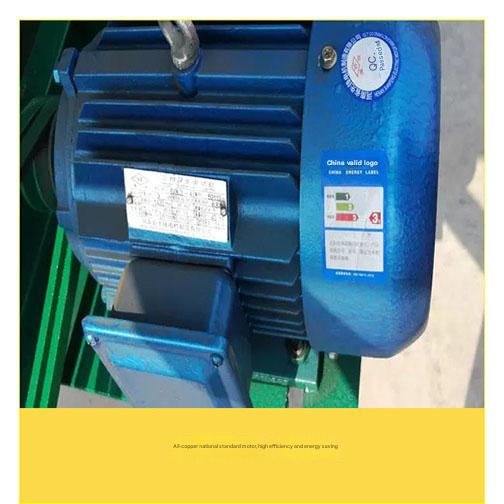

The compound fertilizer inclined disc granulator is mainly composed of inclined granulating disc, driving device, disc inclination adjustment mechanism, frame, feed pipe, hanging plate and other components. The disc adopts an arc structure and is made of high-strength and corrosion-resistant materials. There are several radial reinforcement steel plates at the bottom, which are sturdy and durable. The driving device includes a motor, a reducer, etc., which drives the disc to rotate through transmission parts such as belts and gears.

Working principle

The motor of the compound fertilizer inclined disc granulator outputs power through the reducer, and the granulating disc rotates through the transmission of belts, gears, etc. The evenly mixed compound fertilizer raw materials are evenly added to the inclined disc from the feed pipe. The inclination angle of the disc is usually 35°-55°. During the rotation of the disc, the material is subjected to the effects of gravity, centrifugal force and friction. The small particles continue to roll on the edge of the disc and absorb the surrounding powder, gradually increasing to form particles. When the particles reach a certain strength and size, they will overflow from the edge of the disc.

The reducer and motor are driven by flexible belts, which start smoothly, reduce impact force, and increase the service life of the equipment. The bottom of the pelletizing plate is reinforced with multiple radiant steel plates, which is durable and never deformed. The thicker, heavier and stronger base design does not require anchor bolts to run smoothly.

After the material passes through the compression zone, the pressure on the material gradually decreases, and its surface tension and gravity cause it to escape naturally, enter the pelletizer and pill making machine for crushing and trimming, and then enter the vibrating screen for screening.

Qualified products are sent to the finished product warehouse or directly packaged by the conveyor, and the powdered materials under the screen are sent back to the raw material warehouse through the return device and then rolled twice.

The extrusion force of the compound fertilizer inclined disc granulator can be adjusted by the hydraulic system according to the strength of the particles. By changing the groove shape of the roller surface, flakes, strips, olives, flat balls and other materials can be obtained.