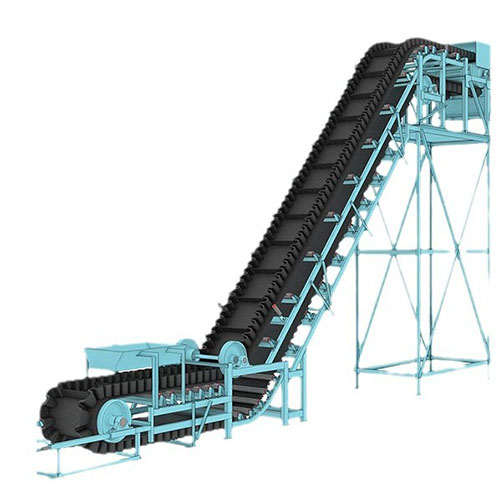

Belt conveyor

- Smooth conveying: The corn flake belt conveyor runs smoothly, which can keep the corn flakes in a relatively stable state during the conveying process, reduce the bumps and collisions of the materials, thereby reducing the breakage rate of the corn flakes and ensuring the integrity of the materials.

- Large conveying capacity: It has strong conveying capacity, and belts of different widths and speeds can be selected according to production needs to achieve large-volume corn flake conveying and meet the requirements of large-scale production.

- Strong adaptability: The corn flake conveyor belt can adapt to different working environments, whether indoors or outdoors, dry or humid, and can operate normally. It can also flexibly carry out horizontal, inclined or curved conveying according to the site terrain and process requirements.

- Easy maintenance: The structure is relatively simple, mainly composed of belts, rollers, rollers and other components. The maintenance and replacement of these components are relatively convenient, with low maintenance costs, which can effectively reduce equipment downtime and improve production efficiency.

- Environmentally friendly and clean: During the conveying process of the corn flaking belt conveyor, the materials are confined on the belt and are not easy to spill or fly. This can effectively avoid the pollution of the working environment by corn flaking and keep the production site clean and hygienic.

The structure of corn flake belt conveyor

- Drive device: generally composed of a motor reducer or electric roller, which provides power for the conveyor to make the conveyor belt run.

- Roller: includes drive roller and bend roller. Drive roller transmits power, and bend roller changes the running direction of conveyor belt.

- Roller group: There are grooved rollers, flat rollers, self-aligning rollers, buffer rollers, etc., which are used to support the conveyor belt and materials and reduce the running resistance of the conveyor belt.

- Frame: The structure that supports the entire conveyor, usually made of steel, to ensure the stability of the conveyor.

- Tensioning device: It enables the conveyor belt to reach the necessary tension to prevent it from slipping on the driving roller and ensure that the deflection of the conveyor belt between the rollers is within the specified range.

- Material: Commonly used conveyor belts are rubber belts and plastic belts. In addition, there are some conveyor belts made of special materials, such as food-grade stainless steel chain conveyor belts, which have the characteristics of good air permeability, large bearing capacity and not easy to leak.

- Shape: There are flat belts and grooved belts. Grooved belts can better convey bulk materials and prevent them from spilling.

Specifications of corn flake conveyor belt

- Bandwidth: Common ones are 500mm, 600mm, 650mm, 800mm, 1000mm, etc.

- Length: It can be customized according to actual needs, generally there are 4 meters, 5 meters, 6 meters, 8 meters, 10 meters, 12 meters, 15 meters and other options.

- Conveying speed: usually adjustable between 0.5-2m/s to meet different production needs.

Applicable scenarios of corn flake belt conveyor

- Agricultural production: Mainly used for the transportation of corn flakes from the production workshop to the warehouse, or from the drying area to the storage location on the farm.

- Food processing: In corn flake processing enterprises, it is used to transport corn flakes to the packaging link or the next processing step.