Microwave drying machine

Efficient and fast

The fully automatic corn flake microwave drying machine can directly act on the inside of the corn flakes, so that the material is heated inside and outside at the same time, without the need for heat conduction process, with a fast heating speed, and can achieve the drying purpose in a short time, greatly improving production efficiency.

Even heating

The microwave field in the fully automatic corn flake microwave dryer is evenly distributed in the drying chamber, which can heat all parts of the corn flakes evenly, avoiding the phenomenon of local over-drying or under-drying caused by uneven heating in traditional drying methods, and ensuring the consistency of product quality.

Small nutritional loss

Due to the short drying time and relatively low temperature, the loss of nutrients such as vitamins and proteins in corn flakes can be effectively reduced, and its nutritional value can be better preserved.

Energy saving and environmental protection

The fully automatic corn flake microwave dryer has high energy conversion efficiency, and the proportion of electrical energy converted into microwave energy is high. Microwaves only heat the materials, and the surrounding environment does not heat up significantly, reducing heat loss. Compared with traditional drying methods, it has significant energy-saving effects.

Easy to control

The fully automatic corn flake microwave dryer can accurately control the drying process by adjusting parameters such as microwave power and drying time, realize automatic operation, meet the drying process requirements of different corn flakes, and ensure stable and reliable product quality.

Safety and Health

The fully automatic corn flake microwave dryer does not emit any harmful gas during the microwave drying process, and microwaves have a certain bactericidal effect. It can sterilize the corn flakes while drying to ensure the hygiene and safety of the product.

Working principle of fully automatic corn flake microwave drying machine

The microwave generator generates microwaves, which penetrate the corn flakes, causing the polar water molecules in the corn flakes to move at high speed under the action of the microwave field and generate heat by mutual friction, thereby achieving internal heating, prompting the rapid evaporation of water and achieving the purpose of drying.

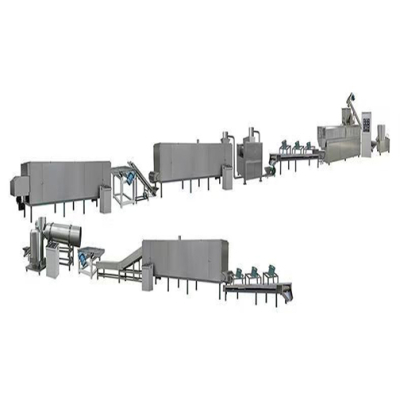

Equipment structure of fully automatic corn flake microwave drying machine

It is usually composed of a feeding system, a microwave drying chamber, a discharging system, a control system, etc. The feeding system uses an automatic feeding device, such as a conveyor belt, which can evenly feed the corn flakes into the drying chamber. The microwave drying chamber is the core component, which is equipped with a microwave generator and a reflector to ensure uniform microwave distribution. The discharging system is used to discharge the dried corn flakes. The control system can realize parameter setting and monitoring of the drying process.

Performance parameters of fully automatic corn flake microwave drying machine

- Power: Common ones are 20kW, 30kW, etc. The greater the power, the stronger the drying capacity.

- Production capacity: Generally, there are different specifications such as 100-150kg, 200-250kg, 300-500kg per hour.

- Microwave frequency: Usually 2450±50MHz.

- Power supply: Generally 380±10V.

Application scope of fully automatic corn flake microwave drying machine

It is suitable for drying corn flakes, and can also be used for microwave heating, drying and sterilization of other cereal flakes, puffed foods, small packaged foods, cakes, biscuits, etc.

After-sales service

Generally, manufacturers will provide a one-year warranty service and free on-site installation and commissioning. They can also provide long-term technical support and spare parts supply to ensure the normal operation of the equipment.