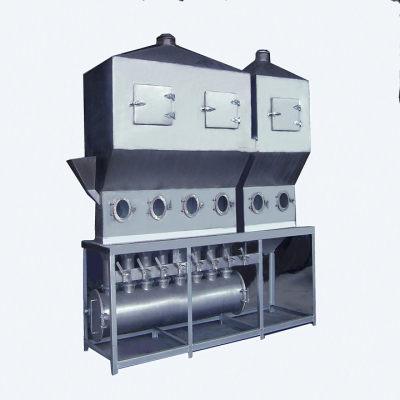

Feed Extruder

Corn flake feed extruder can improve feed quality

- Improve digestibility: Through the puffing process, the starch structure of corn changes and becomes easier to be broken down by animal digestive enzymes, thereby improving the digestibility of feed and enabling animals to better absorb nutrients.

- Kill harmful microorganisms: The high temperature and high pressure conditions during the puffing process can effectively kill harmful microorganisms in corn, such as bacteria, mold and parasite eggs, reducing the risk of animal infection and improving the safety of feed.

Corn flake feed extruder can enhance the palatability of feed

- Optimize taste and flavor: The puffed corn flakes have a unique aroma and crispy taste, which can increase the appetite of animals and improve feed intake.

- Improved appearance: Puffing makes the appearance of corn flakes more regular and attractive in color, which is more attractive to animals than ordinary corn feed.

Corn flake feed extruder has high processing efficiency

- Continuous production: It can realize continuous feeding and discharging, can run stably for a long time, greatly improves production efficiency, and is suitable for large-scale feed production.

- Production flexibility: According to the needs of different animals and feed formulas, corn flake feeds of different specifications and performances can be produced by adjusting the parameters of the extruder to meet diverse market demands.

Corn flake feed extruder can reduce costs

- High raw material utilization rate: The corn is fully processed during the puffing process, which reduces the waste of raw materials, improves the utilization rate of raw materials, and thus reduces production costs.

- Save breeding costs: Due to the improvement of feed digestibility, animal growth rate is accelerated, the breeding cycle is shortened, and feed waste is reduced. All these can reduce breeding costs and improve breeding efficiency.

Corn flake feed extruder is convenient for storage and transportation

- Reduce moisture content: The moisture in the corn will evaporate during the puffing process, and the moisture content of the product is low, generally around 10% - 13%, which is conducive to long-term storage and long-distance transportation, and is not prone to mildew and deterioration.

- Appropriate density: The density of corn flake feed is moderate, which is convenient for packaging and stacking, and will not increase transportation costs due to excessive density, nor will it take up too much storage space due to too low density.

How it works

The corn flake feed extruder uses the unequally spaced non-standard spiral system to push the gas in the material out and quickly fill it with the material. The material is subjected to shear force and refluxes, increasing the pressure in the machine chamber. At the same time, the friction between the spiral and the machine chamber makes the material fully mixed, extruded, heated, glued, and gelatinized. The original structure is destroyed, and the mechanical energy is converted into thermal energy, making the material a gelled state with flow properties. When the material is extruded to the outlet, the pressure changes from high pressure to normal pressure in an instant, and the temperature changes from high temperature to normal temperature in an instant. The water evaporates quickly from the tissue structure, forming countless microporous structures inside it, and then passes through the cutting device, cutting and cooling, that is, expansion forming.

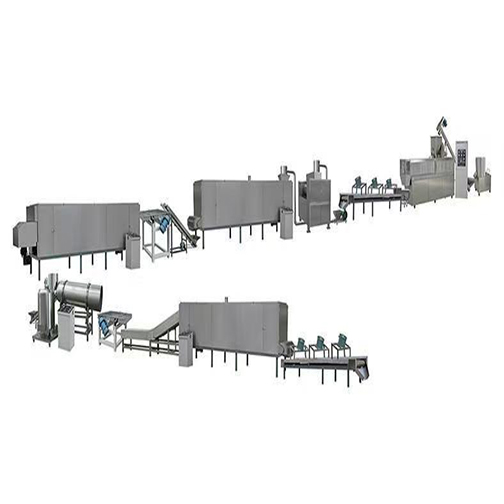

Equipment composition

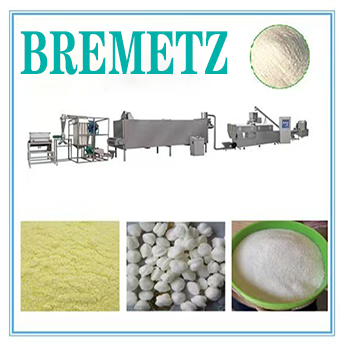

Corn flake feed extruder usually consists of a powder mixer, a feeder, an extruder, a vibrating screen, an air conveyor, a tablet press, etc. The powder mixer mixes corn flour and other raw materials with nutritional additives and water; the feeder conveys the mixed raw materials to the extruder feeding hopper; the extruder produces small spherical particles; the vibrating screen disperses the particles; the air conveyor conveys the particles to the tablet press to be pressed into thin flakes, namely corn flakes.

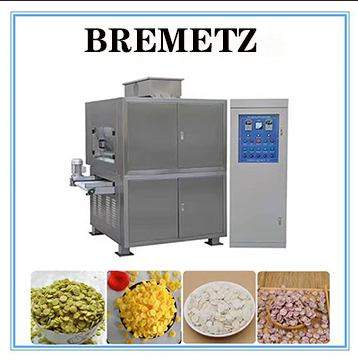

Product features of corn flake feed extruder

- High degree of automation: It adopts advanced automatic control system, which can accurately control parameters such as temperature and speed. The operation is simple and convenient, and only one person is needed to complete the operation of the entire production line.

- Good product quality: It can fully expand the corn, with uniform product structure, good taste and high digestibility. And by controlling the heating temperature and screw speed, the expansion degree of corn flakes can be adjusted to meet different needs.

- Wide range of applications: It can use a variety of raw materials such as rice, corn, oats, buckwheat, soybean meal and starch. By adjusting the formula and process, different types of corn flake feed can be produced to meet the nutritional needs of different animals.

Working environment requirements of corn flake feed extruder

The equipment usually needs to be installed in a dry, well-ventilated workshop with a flat and solid floor to ensure stable operation of the equipment. Avoid installing it in a humid and dusty environment to prevent electrical components from getting damp and short-circuiting, and dust from entering the equipment and affecting performance. At the same time, a stable power supply must be provided, and necessary lighting facilities must be equipped to facilitate operators to operate, maintain and overhaul the equipment.

Maintenance of corn flake feed extruder

Regularly check the various parts of the equipment, such as screws, molds, bearings, etc. If they are worn or damaged, they should be replaced in time. Clean the residual materials inside the equipment to prevent material accumulation from affecting the performance of the equipment. Lubricate the transmission parts to ensure smooth operation of the equipment. In addition, the electrical system needs to be checked to ensure that the line connections are firm to avoid electrical failures.