Hydraulic biogas digester

- Simple structure: The corn flake hydraulic biogas digester is mainly composed of fermentation room, hydraulic room, feed inlet, discharge port and other parts. It has a relatively simple structure, low construction difficulty and low cost, and is suitable for widespread use in rural areas.

- Easy to use: The corn flake hydraulic biogas digester maintains a certain pressure in the biogas digester through the water seal effect of the water pressure chamber. When producing gas, the biogas presses the water into the water pressure chamber, and when using the gas, the water in the water pressure chamber squeezes out the biogas. It is easy to operate and does not require complicated equipment and technology.

- High safety: During normal operation, the pressure in the corn flake hydraulic biogas digester is relatively stable, and there are certain safety protection devices, such as safety valves, which can effectively prevent safety accidents such as biogas leakage and explosion.

- Strong adaptability of raw materials: corn flake hydraulic biogas digester can use corn flakes and other agricultural wastes as fermentation raw materials, which has a wide source and low cost, and can achieve effective utilization of resources and harmless treatment of wastes.

- Good thermal insulation performance: Corn flake hydraulic biogas digesters are generally built underground and are less affected by the outside temperature, which is conducive to maintaining a stable temperature in the digester, providing a more suitable living environment for biogas fermentation microorganisms and improving gas production efficiency.

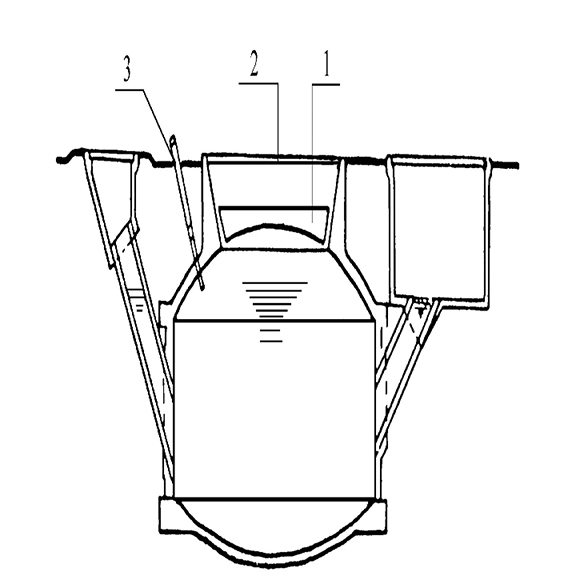

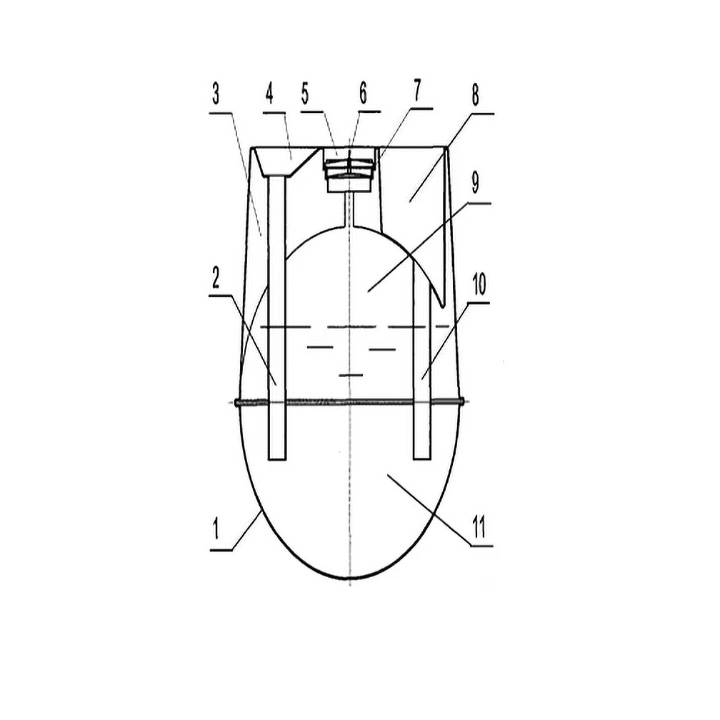

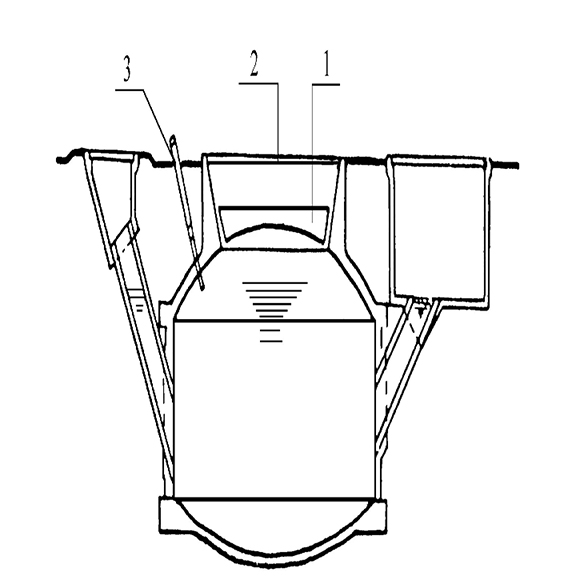

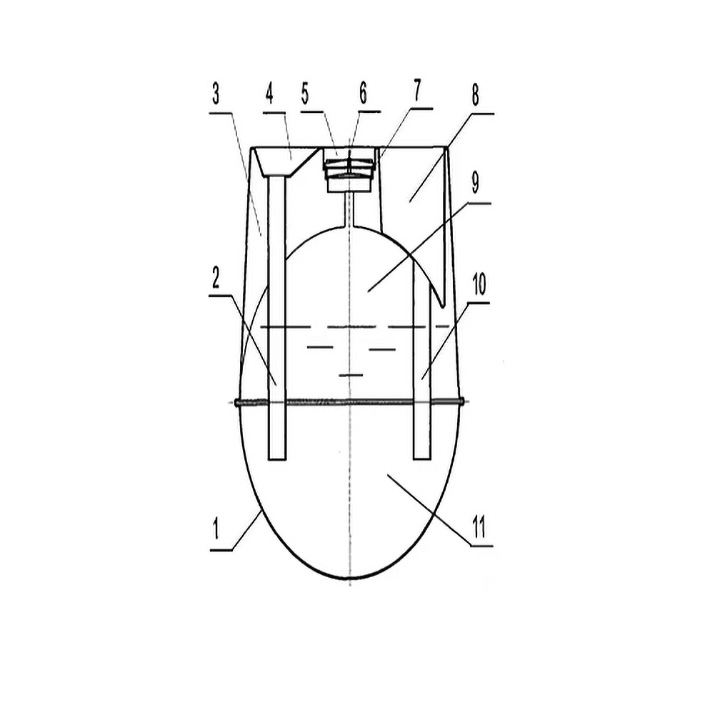

Structural design of corn flake hydraulic biogas digester

- Fermentation room: It is the core part of the biogas digester, used to contain fermentation raw materials such as corn flakes, and provide an anaerobic fermentation environment for microorganisms. It is usually cylindrical, spherical or ellipsoidal in shape.

- Hydraulic room: connected to the fermentation room. When biogas is produced in the fermentation room, the gas pressure increases and the liquid is pressed into the hydraulic room. When the gas is used, the biogas is discharged and the liquid in the hydraulic room flows back to the fermentation room.

- Feed inlet: Located on one side of the biogas tank, it is used to feed corn flakes and other fermentation raw materials, such as human and animal feces, etc. It is generally designed in a trumpet shape for easy feeding.

- Discharge port: It can be set at the bottom or side of the biogas tank to discharge the fermented biogas residue and liquid to provide high-quality fertilizer for agricultural production.

Working principle of corn flake hydraulic biogas digester

As corn flakes and other raw materials ferment in the fermentation room to produce biogas, the pressure in the biogas tank increases, forcing a portion of the liquid to enter the water pressure room, causing the liquid level in the water pressure room to rise and form a water level difference; when the gas is used, the biogas is discharged under the action of the water pressure, the pressure in the biogas tank decreases, the liquid in the water pressure room flows back, the water level difference decreases, and the cycle continues.

Corn flake hydraulic biogas digester performance parameters

- Gas production rate: Under suitable fermentation conditions, with corn flakes as the main raw material, the gas production rate can usually reach 0.3-0.5 cubic meters/cubic meters·day.

- Fermentation temperature: Medium temperature fermentation is generally controlled at 30-35℃, high temperature fermentation is at 50-55℃, and room temperature fermentation is affected by the external environment temperature.

- pH value: The pH value of the fermentation liquid is generally controlled between 6.5-7.5, which is conducive to the growth and metabolism of biogas microorganisms.

Corn flakes hydraulic biogas digester raw material requirements

- Corn flakes: It is the main raw material, providing rich carbohydrates and other nutrients. It needs to be pre-treated, such as crushing and soaking, to increase the contact area between the raw materials and microorganisms and improve the fermentation efficiency.

- Inoculants: Activated sludge and livestock manure at the bottom of the biogas digester can be used. They contain a large number of biogas microorganisms, which can speed up the fermentation start-up speed and improve the gas production efficiency.

- Other raw materials: It can be matched with human and animal manure, straw, etc. to adjust the carbon-nitrogen ratio and provide comprehensive nutrients for microbial growth.

Corn flake hydraulic biogas digester supporting equipment

- Desulfurizer: used to remove harmful gases such as hydrogen sulfide in biogas, protect biogas stoves, lamps and other equipment, and extend their service life.

- Pressure gauge: installed on the biogas digester or gas pipeline, used to monitor the pressure changes in the biogas digester, so as to grasp the operation status of the biogas digester in time.

- Biogas stoves and lamps: select suitable biogas stoves and lamps according to actual needs for cooking, lighting, etc.

Installation and maintenance of corn tablet hydraulic biogas digester

- Installation: Choose a place with high terrain, dryness, flatness and far away from fire sources and buildings to build the digester, and carry out construction steps such as digging pits, pouring, and installation according to design requirements to ensure the sealing and structural stability of the digester.

- Maintenance: Regularly check the sealing of the digester, whether the pipeline connection is firm, observe the changes in the pressure gauge value, replenish the fermentation raw materials in time, and regularly clean the digestate and liquid at the discharge port to ensure the normal operation of the digester.