Ultrasonic vibrating screen

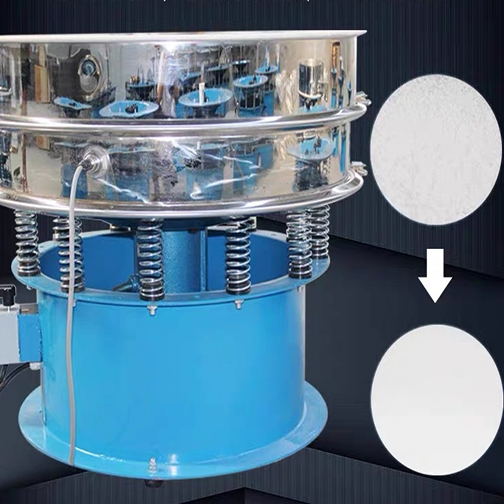

- High-efficiency screening: The corn flake ultrasonic vibrating screen combines ultrasonic technology with a vibrating screen, which can effectively eliminate the problem of screen clogging, greatly improve the screening efficiency of corn flakes, and increase the processing capacity several times more than ordinary vibrating screens.

- High-precision screening of corn flakes with ultrasonic vibration screen: Ultrasonic vibration can make the material more evenly distributed and move on the screen surface, thereby achieving more accurate particle size classification, which can meet the production needs with higher requirements on corn flake particle size.

- Protect the screen: The ultrasonic vibrating screen of corn flakes can reduce the wear and impact of materials on the screen, extend the service life of the screen, and reduce the replacement frequency and cost of the screen.

- Wide range of applications: The corn flake ultrasonic vibrating screen is not only suitable for screening ordinary corn flakes, but also for effectively screening some corn flakes with high viscosity, high humidity or fine particle size, which expands the application range of the equipment.

- Corn flake ultrasonic vibrating screen is clean and environmentally friendly: it adopts a fully enclosed structure and the ultrasonic self-cleaning function to effectively prevent dust from spilling out, reduce pollution to the working environment, and avoid material waste.

- Intelligent control: The corn flake ultrasonic vibrating screen has an advanced control system that can accurately adjust the power and frequency of the ultrasonic wave and the amplitude and frequency of the vibrating screen according to different screening requirements, realize intelligent operation, and improve the degree of automation and stability of production.

Working principle of corn flake ultrasonic vibrating screen

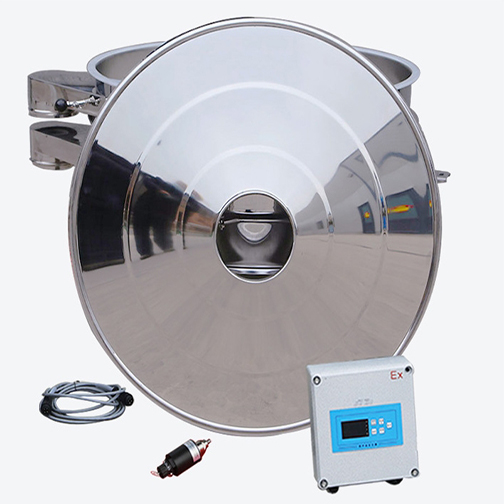

The electric energy of 220V, 50Hz or 110V, 60Hz is input into the ultrasonic transducer and converted into 36KHz mechanical vibration, which makes the screen vibrate at a high frequency of 36,000 times per second, so that the corn flakes form a micro-suspension state on the screen and pass through the screen quickly to achieve screening and cleaning.

Structural design of ultrasonic vibration screen for corn tableting

- Material: Mostly made of SUS304 stainless steel, which is corrosion-resistant and ensures that the equipment is not easily damaged in a humid environment or when in contact with corrosive materials.

- Screen: Usually a wire mesh with various mesh sizes, which can be selected according to the particle size requirements of corn flakes.

- Vibration source: generally composed of an ultrasonic generator and a vibration motor, providing stable ultrasonic vibration and screen body vibration.

Corn flake ultrasonic vibrating screen performance characteristics

- High-precision screening: It can achieve accurate particle size classification and effectively control the particle size range of corn flakes.

- High screening efficiency: It solves the problem of screen clogging, greatly improves screening efficiency, and can increase the processing capacity several times compared with ordinary vibrating screens.

- Screen self-cleaning function: reduces the frequency of screen cleaning and extends the service life of the screen.

Corn flake ultrasonic vibrating screen model specifications

Common models include 1-2 layers with a diameter of 400-1500mm, and can also be designed into special models such as edge-added type and gate type.

Corn flake ultrasonic vibrating screen technical parameters

- Power: Varies according to the device model, such as DHC-400 is 0.18KW, DHC-1000 is 0.75KW.

- Screen specifications: The mesh size is usually between 80-600 mesh, which can meet different screening accuracy requirements.