Vibrating cooler

- The corn flake vibrating cooler has high cooling efficiency: the corn flakes are constantly turned over by vibration during the cooling process, fully contacting with the cold air, increasing the cooling area, and can quickly and effectively reduce the temperature of the corn flakes, thereby improving production efficiency.

- Uniform cooling: The vibration effect makes the corn flakes evenly distributed and moved in the cooler, avoiding local accumulation, ensuring that each corn flake can be evenly cooled, and the product quality is more stable.

- Simple structure: The corn flake vibrating cooler is mainly composed of a vibration device, a cooling air duct, a trough, etc. The structure is relatively simple, without complex transmission parts, reducing equipment failure points and reducing maintenance costs.

- Easy operation: The vibration frequency and amplitude of the corn flake vibrating cooler can be adjusted according to actual production needs to meet the requirements of different outputs and corn flake characteristics. The operation is simple and convenient, and easy to master.

- Small footprint: The equipment is compact. Compared with some other types of cooling equipment, it occupies a smaller area under the same processing capacity, which can effectively save production workshop space.

- Energy saving and environmental protection: The corn flake vibrating cooler uses the vibration principle to achieve material conveying and cooling, and the energy consumption is relatively low. At the same time, good sealing performance reduces cold air leakage, improves energy utilization efficiency, and meets the requirements of energy saving and environmental protection.

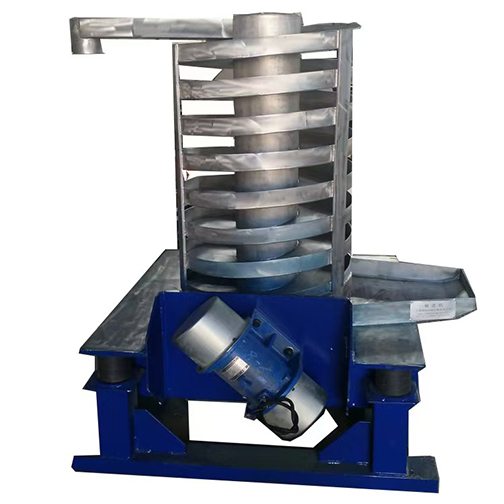

Corn flake vibrating cooler structure

- Vibration device: usually composed of a vibration motor or other vibration drive mechanism, which generates vibration to evenly distribute and move the corn flakes in the cooler.

- Cooling air duct: a reasonable air duct structure is designed to allow cold air to blow evenly through the corn flakes to achieve efficient cooling.

- Feed trough: used to carry corn flakes, generally made of wear-resistant and corrosion-resistant materials, such as stainless steel, to ensure the service life of the equipment and product quality.

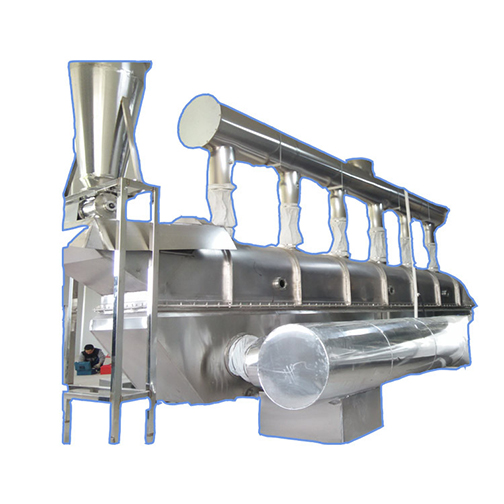

Working principle of corn flake vibrating cooler

After corn flakes enter the corn flake vibrating cooler from the feed port, they vibrate back and forth or in a circular motion along the feed trough under the action of the vibrating device. At the same time, cold air is sent into the cooler through the air duct, fully contacts the corn flakes, takes away the heat, and cools the corn flakes. The cooled corn flakes are discharged from the discharge port.

Corn flake vibrating cooler technical parameters

- Processing capacity: Depending on the model and specifications, the processing capacity is generally between several tons and tens of tons per hour.

- Vibration frequency and amplitude: The vibration frequency is usually between hundreds and thousands of times per minute, and the amplitude is between a few millimeters and tens of millimeters, which can be adjusted according to actual needs.

- Cooling air volume and wind speed of corn flake vibrating cooler: The air volume is generally between thousands of cubic meters and tens of thousands of cubic meters per hour, and the wind speed is between several meters and more than ten meters per second to ensure a good cooling effect.

- Power: The power of the equipment varies depending on factors such as processing capacity and vibration motor power, and is generally between several kilowatts and tens of kilowatts.

Corn flake vibrating cooler maintenance

- Regular inspection: Regularly check the components of the vibrating device, such as motors, springs, etc., to ensure their normal operation and replace worn or damaged parts in time.

- Clean the air duct: Regularly clean the dust and debris in the cooling air duct to ensure that the air duct is unobstructed to improve cooling efficiency.

- Clean the trough: After each use, the corn flake residue in the trough should be cleaned in time to prevent material accumulation and mildew, which will affect equipment performance and product quality.