Grate Cooler

High cooling efficiency: The organic fertilizer grate cooler uses grate plates to transport materials. The air passes through the bottom of the grate plates and fully contacts the materials for heat exchange. It can quickly cool the high-temperature organic fertilizer to the required temperature, greatly improving production efficiency.

Uniform cooling: The organic fertilizer grate cooler rationally designs the grate plate structure and airflow distribution, so that the material can be evenly exposed to the cold air during the cooling process, avoiding local overheating or overcooling, and ensuring the consistency of the cooling quality of the organic fertilizer.

The organic fertilizer grate cooler has good energy-saving effect: the heat exchange principle is used in the cooling process to recover part of the heat for preheating the combustion air or other process links, which reduces energy consumption and saves production costs.

Large processing capacity: The organic fertilizer grate cooler can be designed and configured according to the production scale, can meet the needs of large-scale organic fertilizer production, has strong processing capacity, and can continuously and stably cool a large amount of organic fertilizer.

Stable and reliable operation: The organic fertilizer grate cooler has a simple structure, and key components such as grate plates are made of wear-resistant and high-temperature resistant materials. It has high strength and stability, reduces equipment failures and maintenance times, and can operate stably for a long time.

High degree of automation: The organic fertilizer grate cooler is equipped with an advanced automatic control system, which can realize precise control and monitoring of parameters such as temperature, air volume, material conveying speed, etc. during the cooling process, reduce manual intervention, and improve production stability and controllability of product quality.

Excellent environmental performance: During the cooling process, the organic fertilizer grate cooler reduces dust emissions and environmental pollution through effective sealing and dust collection devices, which meets environmental protection requirements.

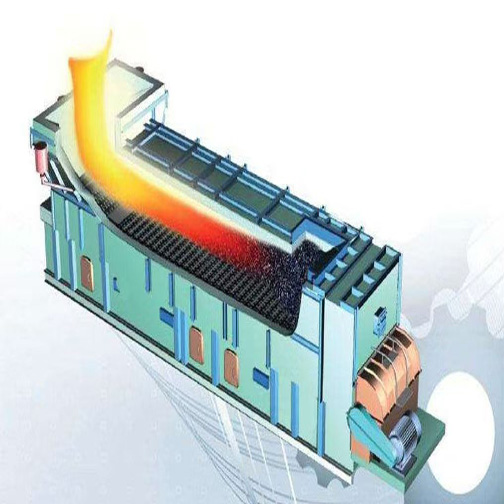

How it works

Organic fertilizer grate cooler After the organic fertilizer enters the cooler from the feed port, it forms a material layer of a certain thickness on the grate plate. The cold air blown in by the blower passes through the moving material layer on the grate bed in a vertical direction, fully exchanges heat with the organic fertilizer, and thus the organic fertilizer is cooled quickly.

Organic fertilizer grate cooler structure

- Grate bed: It is the main component of the organic fertilizer grate cooler. It consists of fixed grate plates and movable grate plates arranged in rows and intervals. It is used to carry and transport organic fertilizer materials.

- Wind chamber: located below the grate bed, used to contain the blown cold air so that the air can evenly pass through the grate plate into the material layer.

- Transmission device of organic fertilizer grate cooler: used to drive the grate plate to move, so that the material moves forward continuously on the grate bed to ensure the continuity of the cooling process.

- Feeding and discharging device: It includes a feeding port and a discharging port. The feeding port is used to feed the organic fertilizer to be cooled into the cooler, and the discharging port is used to discharge the cooled material.

- Sealing device: prevents cold air leakage, ensuring cooling effect and system stability.

Technical parameters of organic fertilizer grate cooler

- Production capacity: Depending on the different models and specifications, the production capacity generally ranges from several tons to tens of tons per hour.

- Cooling efficiency: High-temperature organic fertilizer can be cooled to a lower temperature within minutes, for example, from several hundred degrees Celsius to below 100°C.

- Grate width and length: Common grate width may be around 1-3 meters, and the length depends on the overall size and production capacity of the equipment, generally between several meters and more than ten meters.

- Fan power: Depending on the size of the chiller and the cooling requirements, the fan power usually ranges from several kilowatts to tens of kilowatts.

Application scope of organic fertilizer grate cooler

It is mainly used in the process of organic fertilizer production to cool organic fertilizer particles or powdered materials after drying or high temperature treatment. It is suitable for organic fertilizer production enterprises of various sizes and can be used in conjunction with other equipment on the organic fertilizer production line, such as dryers, granulators, etc.