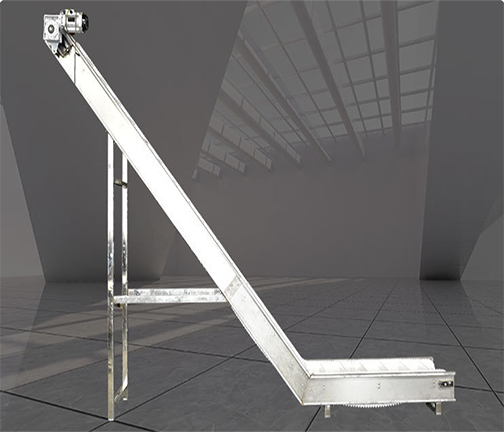

Belt elevator

- The corn flake belt elevator has smooth transportation: it uses a conveyor belt as the conveying medium, which runs smoothly and can reduce the breakage and damage of corn flakes during transportation, thus ensuring product quality.

- The corn flake belt elevator has a large conveying capacity: by adjusting the width and running speed of the conveyor belt, the requirements for a larger conveying capacity can be achieved to meet the needs of large-scale corn flake production.

- Corn flake belt elevator has high lifting height: it can achieve a high lifting height and can lift corn flakes to different heights for subsequent processing or storage according to the layout and process requirements of the production workshop.

- The corn flake belt elevator has strong adaptability: it has good adaptability to the moisture, particle size and other characteristics of corn flakes, and can smoothly transport dry or slightly moist corn flakes.

- Corn flake belt elevator is easy to maintain: the structure is relatively simple, and the main components are conveyor belts, rollers, rollers, etc., which are easy to maintain and reduce the maintenance cost and downtime of the equipment.

- Corn flaking belt elevator is environmentally friendly and clean: the conveyor belt has good sealing properties, which can effectively prevent the leakage of corn flaking dust, keep the working environment clean and hygienic, and meet environmental protection requirements.

Working principle of corn flake belt elevator

The conveyor belt is driven by a motor. Through the circulation of the conveyor belt, the corn flakes are lifted from a lower position to a higher position, thus realizing vertical transportation of materials.

The structure of corn flake belt elevator

- Conveyor belt: Mostly use wear-resistant and stretch-resistant rubber belts or PVC belts. Some high-end products use polyurethane belts, which are wear-resistant, anti-aging and have long service life.

- Driving device: usually composed of a motor, a reducer, a coupling, etc., which provides power for the conveyor belt so that the conveyor belt can run at a stable speed.

- Roller: including driving roller and redirecting roller. The driving roller is connected to the driving device and drives the conveyor belt to operate through friction;

The redirecting roller is used to change the running direction of the conveyor belt, so that the conveyor belt forms a closed loop.

Technical parameters of corn flake belt elevator

- Conveying capacity: small equipment may have a conveying capacity of several tons per hour, while large equipment can reach dozens of tons or even hundreds of tons. For example, a 500mm wide elevator generally has a conveying capacity of 10-30 tons per hour; a 800mm wide elevator can have a conveying capacity of 30-80 tons per hour.

- Lifting height: generally ranging from a few meters to dozens of meters, the common lifting height is 5-30 meters.

- Conveyor belt speed: The speed range is usually between 0.5-2 m/s and can be adjusted according to the conveying volume and material characteristics.

Product features of corn flake belt elevator

- Smooth conveying: Smooth operation can reduce the breakage and damage of corn flakes during conveying.

- Large conveying capacity: The requirement for larger conveying capacity can be achieved by adjusting the width and running speed of the conveyor belt.

- High lifting height: It can achieve a higher lifting height to meet the needs of different production layouts.

- Strong adaptability: It has good adaptability to the moisture, particle size and other characteristics of corn flakes.

Application areas of corn flaking belt elevator

It is mainly used in corn flake production enterprises, feed processing plants, farms and other places. In the production process of corn flakes, it is used to transport raw corn or flaked corn to different processing links or storage locations.