Large granulator

The inorganic fertilizer disc granulator has a wide range of applications and its advantages are as follows:

No drying process is required, granulation is performed at room temperature, one-time molding, low investment, quick results, and good economic benefits.

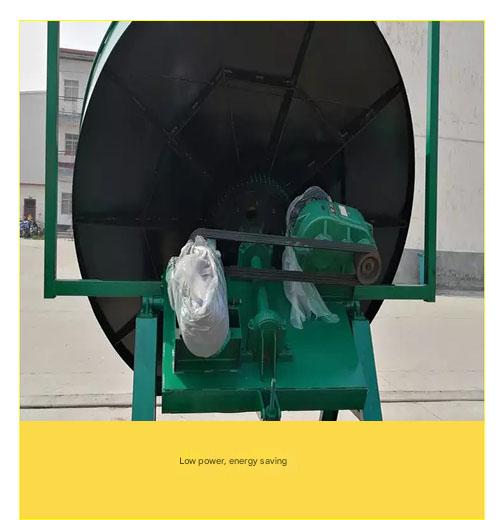

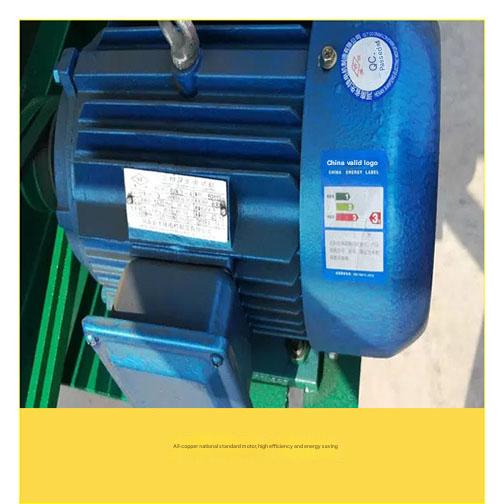

2. Low power, reliable operation, no three wastes discharge, stable operation, convenient maintenance, reasonable process layout, advanced technology, and low production cost.

3. The raw material adaptability is wide, and it can be used for granulation of various raw materials such as compound fertilizer, medicine, chemical industry, feed, coal, metallurgy, etc., and can produce various concentrations and types of compound fertilizers (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.).

4. In particular, the granulation of compound fertilizers such as rare earth, ammonium carbonate, and ammonium sulfate is a national environmental protection applicable technology promotion project.

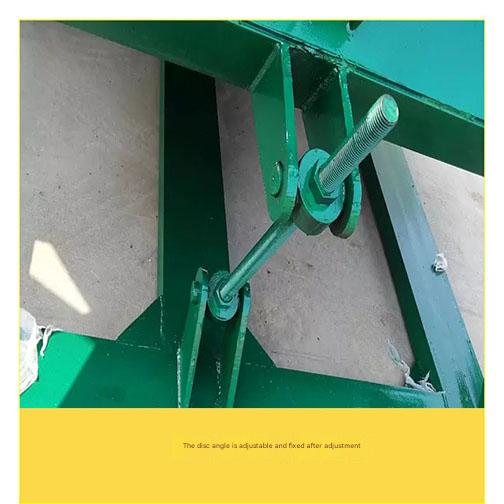

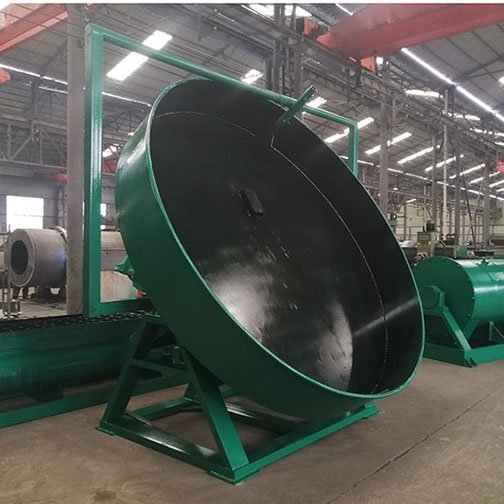

The inorganic fertilizer disc granulator adopts an overall arc structure, and the granulation rate can reach more than 93%. The granulation disc is equipped with three discharge ports, which is convenient for intermittent production operation, greatly reduces labor intensity, and improves labor efficiency. The reducer and motor are driven by flexible belts, which start smoothly, reduce impact force, and extend the service life of the equipment. The bottom of the pelletizing plate is reinforced with multiple heat dissipation steel plates, which is durable and will never deform. The thickened and heavy solid base design does not require anchor bolts and runs stably.

1. Working principle of inorganic fertilizer disc granulator: The disc is driven by the motor through the reducer, and the material is added from the top of the disc. During the rotation process, the material rolls in the disc under the action of centrifugal force, friction and gravity, and continuously agglomerates into granules. When the granules reach a certain size and weight, they are discharged from the edge of the disc.

2. Structural features of inorganic fertilizer disc granulator: It is mainly composed of a disc, a drive device (motor, reducer), a frame, a scraper device, etc. The disc is generally made of high-quality steel plate with good wear resistance; the scraper device can timely clean the material adhering to the inner wall and bottom of the disc to ensure the normal granulation.

The inorganic fertilizer disc granulator is a kind of granulator. The disc is lined with high-strength glass fiber. It has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life. It is an ideal granulation equipment.

Various dry powder materials are added from the top of the equipment, and after degassing and spiral pre-pressing, they are conveyed to the arc-shaped groove of the two rollers. The two rollers rotate at the same speed and in opposite directions, bite the materials into the groove, and compress them strongly. After the material passes through the compression zone, the pressure on it gradually decreases, and its surface tension and gravity make it escape naturally, enter the granulator and pill making machine for crushing and trimming, and then enter the vibrating screen for screening.

Qualified products are sent to the finished product warehouse or directly packaged via a conveyor. The powdered materials under the screen are sent back to the raw material warehouse for secondary rolling through the return device. The size of the extrusion force can be adjusted by the hydraulic system according to the needs of particle strength. By changing the groove shape of the roller surface, materials in the shape of flakes, strips, olives, flat balls, etc. can be obtained.

The inorganic fertilizer disc granulator is composed of a large disc, a large gear, a transmission part, a frame, a base, a scraper frame, a non-powered scraper, etc.

The main machine of the inorganic fertilizer disc granulator includes a frame, an adjustment part, and a granulating disc;

A main reducer with a pulley on the input shaft and a pinion on the output shaft;

A main motor with a pulley;

The supporting granulating disc device includes a main shaft, two sets of roller bearings and two bearing seats;