Vibrating screen

- High-precision screening: The corn flake vibrating screen uses the three-dimensional rotary vibration force generated by the vibration motor to make the material do complex rotation and jumping movements on the screen surface, which can more fully contact the screen and achieve high-precision screening. It can effectively separate corn flakes of different particle sizes and meet the strict requirements for product particle size classification.

- Good sealing: The corn flake vibrating screen adopts a fully enclosed structure design and is equipped with sealing devices such as rubber sealing rings, which can effectively prevent the dust from being blown out during the screening process of corn flakes, avoiding dust pollution of the working environment, and also reducing material waste, meeting environmental protection and hygiene standards.

- Flexible and changeable: The corn flake vibrating screen can flexibly change the material's movement trajectory and screening effect according to different screening needs by adjusting the eccentric block angle, amplitude, frequency and other parameters of the vibration motor. It can adapt to a variety of corn flake screening processes and can also achieve multi-stage screening of corn flakes with different particle size ranges by increasing or decreasing the number of screen layers.

- Low noise operation: The corn flake vibrating screen has adopted a series of noise reduction measures in structural design and material selection, such as the use of elastic support devices, shock-absorbing rubber, etc., which effectively reduce the noise generated when the equipment is running and create a relatively quiet working environment for operators.

- Easy maintenance: The overall structure of the corn flake vibrating screen is relatively simple, and the screen can be replaced quickly and easily. Just loosen the fixing device to easily remove the old screen and replace it with a new one. In addition, the various parts of the equipment are easy to disassemble and assemble, which is convenient for daily inspection, cleaning and maintenance, reducing equipment downtime and improving production efficiency.

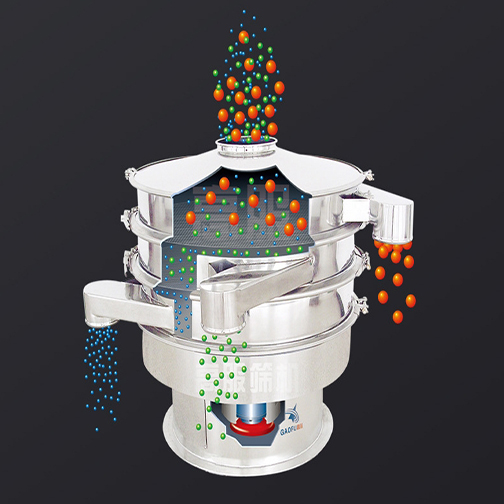

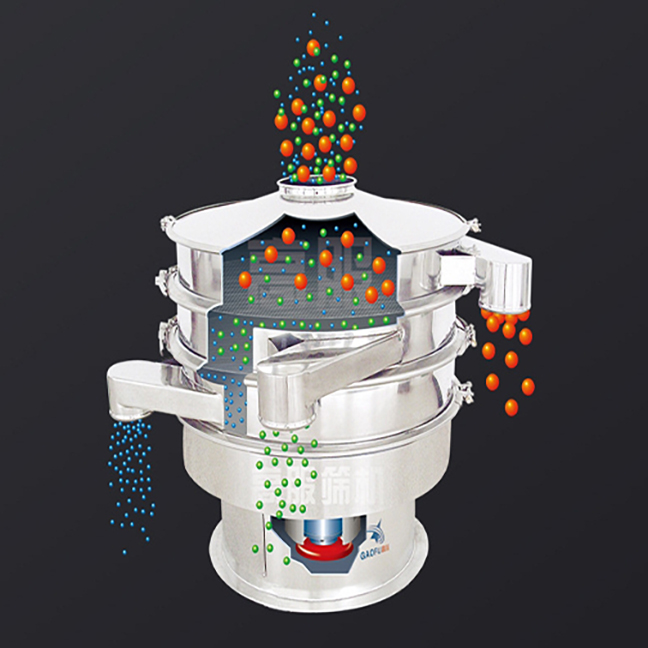

How it works

The corn flake vibrating screen uses a vertical motor as the excitation source. Eccentric weights are installed at the upper and lower ends of the motor to convert the motor's rotational motion into horizontal, vertical and inclined three-dimensional motion, and then transmit this motion to the screen surface, so that the material makes an outward expansion involute motion on the screen surface. The material smaller than the screen hole passes through the screen, thereby realizing the screening of the material.

The structure of corn flake vibrating screen

- Screen box: It is welded from plates of different materials and is used to support and fix the screen and other components.

- Screen: Usually made of stainless steel woven mesh, perforated plate and other materials, it is the key component to achieve screening.

- Vibration motor: provides power source for the equipment. The vibration amplitude and frequency can be changed by adjusting the eccentric block angle of the motor.

- Vibration motor: provides power vibration source for the equipment. The amplitude and frequency can be changed by adjusting the eccentric block angle of the motor.

- Base: used to support the entire device and ensure its stability.

Technical parameters of corn flake vibrating screen

- Model specifications: Common ones include DH-600, DH-800, DH-1000, DH-1200, DH-1500, DH-1800, DH-2000, etc., with diameters ranging from 600mm to 2000mm.

- Screen area: from 0.24m2 to 3.01m2.

- Screen specifications: generally 2-500 mesh, you can choose screens with different meshes according to your needs to achieve accurate grading of corn flakes.

- Feed size: Different models have different feed size requirements, such as DH-600's feed size is less than Φ10mm, DH-800's is less than Φ15mm, DH-1000's is less than Φ20mm, etc.

- Vibration rate: usually 1500rpm.

- Power: The motor power range is 0.25-3Kw.

Application fields of corn flake vibrating screen

It is mainly used for cleaning or grading raw materials in flour making, feed, rice milling, chemical industry, food, oil pressing and other industries. It can clean various granular materials such as corn, wheat, rice, oil and so on.