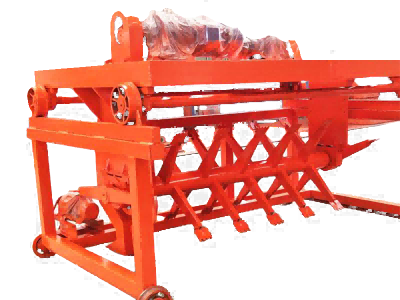

Fully automatic mixer

1. Efficient mixing to ensure quality

High mixing efficiency: The organic fertilizer fermentation horizontal mixer uses spiral blades or planetary blades to physically mix granular fertilizers of different particle sizes, densities, and nutrient contents, and produces tumbling, convection, and shearing movements in the cylinder to achieve rapid and uniform mixing.

High mixing uniformity: Compared with traditional manual mixing or simple mechanical mixing, the BB fertilizer mixer can break the boundaries between particles, ensure that each batch of fertilizers can achieve a stable mixing effect, and avoid the problem of uneven fertilizer nutrient distribution.

2. Accurate control and flexible formula

Fully automatic control: The organic fertilizer fermentation horizontal mixer uses an automatic control system to accurately control the mixing time, speed, and feed ratio to meet the fertilization needs of different crops and different soils.

Flexible formula: According to the needs of soil testing and formula fertilization, the fertilizer mixer can easily adjust the ratio of nitrogen, phosphorus, potassium, and trace elements to produce special fertilizers of various specifications.

3. Energy saving and environmental protection, reducing costs

Low energy consumption: The organic fertilizer fermentation horizontal mixer adopts advanced mixing technology and efficient motor drive. Compared with traditional mixing equipment, it has lower energy consumption and more economical operating costs.

Environmental protection and safety: During the mixing process, the organic fertilizer fermentation horizontal mixer can effectively reduce dust flying, improve the working environment, and protect the health of operators. At the same time, due to the high mixing uniformity, fertilizer waste is reduced, which is beneficial to environmental protection.

4. Compact structure and small footprint

Compact design: The organic fertilizer fermentation horizontal mixer has a compact structure and a small footprint. It is suitable for all kinds of enterprises, especially small and medium-sized fertilizer production enterprises with limited space.

Easy installation and maintenance: The organic fertilizer fermentation horizontal mixer has flexible installation methods, and can be installed on a steel platform or floor-standing. At the same time, the equipment has multiple openings for easy maintenance and cleaning, and simple operation.

5. Large output and strong adaptability

Strong production capacity: The organic fertilizer fermentation horizontal mixer has a large production capacity and can meet the needs of large-scale fertilizer production. Depending on the model and configuration, the output per hour ranges from a few tons to dozens of tons.

Strong adaptability: The organic fertilizer fermentation horizontal mixer is not only suitable for the mixing of organic fertilizer and compound fertilizer, but can also be used under the dust collector of thermal power plants, as well as in chemical, metallurgy, mining, building materials and other industries.

The organic fertilizer fermentation horizontal mixer produced by our company adopts positive and negative action, and mixes and outputs materials through a special internal spiral mechanism and three-dimensional structure. The equipment is novel in design and strong in practicality. Its feeding system does not store materials, the mixing system mixes evenly, and the electronic control system, manual, automatic, and composite settings are all features that similar products do not have.

The blended fertilizer production line can be designed and manufactured according to the requirements of compound fertilizer plants and fertilizer dealers, with an output of 10,000 to 100,000 tons. The process of direct feeding through the lifting trough and direct discharge from the mixer achieves almost zero material dripping.

The compound fertilizer fermentation horizontal mixer equipment has the advantages of long service life, convenient operation, strong reliability, high output, simple maintenance, low cost, time-saving and labor-saving maintenance, and reduced downtime.

Organic fertilizer mixer, also known as blended fertilizer mixer, is mainly used to evenly mix granular fertilizers of different particle sizes, densities, and nutrient contents. It adopts physical mixing method and a special mixing mechanism to achieve full mixing of fertilizers. It is one of the important equipment in modern precision agriculture.

Organic fertilizer fermentation horizontal mixer usually composed of mixing drum, spiral blades (or planetary blades), drive device, control system, feeding system, discharging system and other parts. Some complete sets of equipment may also include storage bins, feeders, metering scales, high-angle belt elevators, quantitative packaging machines, automatic bag sewing machines, finished product conveyor belt conveyors and other auxiliary equipment.