Multifunctional blender

The organic fertilizer vertical mixer has the following advantages:

1. High mixing uniformity: The organic fertilizer vertical mixer adopts a unique mixing structure and rotation method, which can make the organic fertilizer raw materials fully turned and mixed during the mixing process, ensuring the uniform distribution of various components, effectively avoiding the problem of uneven local components, and improving the quality stability of organic fertilizer.

2. Prevent material segregation: The vertical design makes the material subject to the combined effect of gravity and stirring force during the mixing process, which is more conducive to reducing the segregation of materials, especially for materials of different particle sizes and densities, it can maintain a better mixing state.

3. Small footprint: Compared with the horizontal mixer, the organic fertilizer vertical mixer is arranged in a vertical direction. Under the same production capacity, its footprint is usually smaller, which is suitable for use in production sites with limited space, and can effectively improve the utilization rate of the site.

4. Less material residue: The structure of the organic fertilizer vertical mixer is relatively simple, without complex transmission parts and dead corners inside. The material can be discharged more thoroughly after the mixing is completed, reducing the residue of the material in the equipment, reducing the difficulty of cleaning, and avoiding the contamination of the residual material to the next batch of products.

5. Low energy consumption: Due to its mixing principle and structural characteristics, the vertical mixer has relatively small power and low energy consumption when achieving the same mixing effect, which helps to reduce production costs.

6. Easy operation: The operation of the equipment is relatively simple, the control system is easy to master, and workers can operate it proficiently after simple training. The equipment runs stably and maintenance is also relatively convenient, which can effectively improve production efficiency.

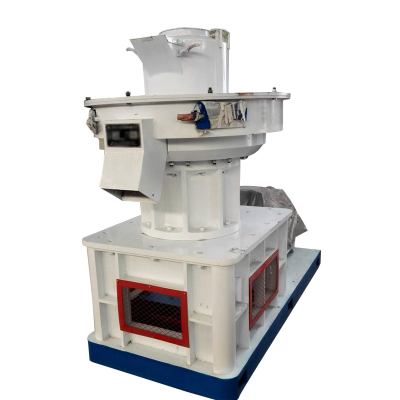

The structure of the organic fertilizer vertical mixer

It is mainly composed of a mixing plate, a discharge port, a mixing arm, a frame (or bracket), a gear box and a transmission mechanism. There are usually fixed mixing teeth on the mixing shaft, and the motor provides power to drive the various parts of the mixer to work.

Working principle of organic fertilizer vertical mixer

The motor drives the mixing shaft to rotate. When the spiral mixing blades or multi-layer paddles on the mixing shaft rotate, the material is lifted from the bottom to the top and then falls back along the wall of the cylinder, forming an efficient vertical circulation, or multi-layer paddles operate at different heights at the same time, so that the material can be fully rolled and staggered in the mixing chamber to achieve uniform mixing.

Performance characteristics of organic fertilizer vertical mixer

Not easy to stick and wear-resistant: The pan is lined with polypropylene plate or stainless steel plate, which has the characteristics of not easy to stick and wear-resistant, which can reduce material residue, reduce the difficulty of cleaning, and extend the service life of the equipment.

- Compact structure and easy operation: It adopts cycloidal pinwheel reducer, which has compact structure, small footprint, easy operation, easy to master the control system, and workers can operate it proficiently after simple training.

- Convenient unloading and transportation: It is designed with a discharge port, which is convenient and fast to unload. It cooperates well with the belt conveyor and can smoothly transport the mixed materials to the next process.

- High production efficiency: The mixing speed is fast and it can work continuously. Through optimized design, the mixing time of a single batch can be shortened by 20%-30%. It is suitable for small and medium-sized production, especially for occasions with limited space.

Operation process

Before starting the machine, check whether there are any debris in the pan, whether the bolts in various parts are loose, whether the reducer oil is sufficient, etc. When starting the machine, it is necessary to start it without load, listen for any abnormal sounds after starting, and then add materials strictly according to regulations. When stopping the machine, it is necessary to wait until the materials in the pan are put out, and clean up the remaining materials in the pan after stopping.

About the maintenance of organic fertilizer vertical mixer

Regularly check the key components such as mixing blades, motors, transmission devices, etc., replace worn parts in time, and lubricate and maintain the equipment. After each production, clean up the residual materials inside the mixer in time to prevent the materials from corroding the equipment. If conditions permit, introduce an intelligent monitoring system to monitor the operating parameters in real time and discover potential problems in advance