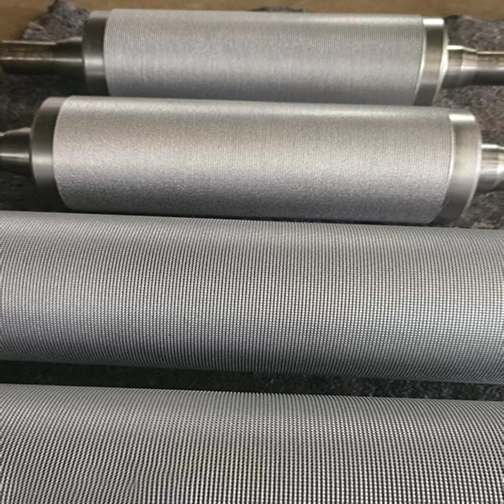

Patterned sheeting roller

- Increase friction: The pattern on the surface of the corn flaking roller can increase the friction between the corn particles, so that the corn is subjected to more uniform force during pressing, which helps to press the corn into thin flakes of uniform thickness, improve the quality of flaking and production efficiency.

- Corn flaking roller improves product characteristics: The pressed corn flakes have patterns, which increase the surface area, facilitate the dissipation of moisture in the subsequent drying process, shorten the drying time and reduce energy consumption. At the same time, the pattern can also improve the palatability of corn flakes in animal feed, make it easier for animals to eat, and help improve digestibility.

- Corn flaking roller reduces adhesion: The pattern can form a certain gap between corn flakes, reduce the adhesion between corn flakes during the flaking process, make the pressed corn flakes easier to separate, and improve the product qualification rate and smoothness of production.

- Enhanced durability: Compared with the smooth flaking roller, the pattern on the surface of the corn flaking roller disperses the pressure to a certain extent, reduces the wear on the roller surface, thereby extending the service life of the flaking roller and reducing the maintenance cost and replacement frequency of the equipment.

Structural design of corn flake pattern roller

- Roller material: usually high-nickel-chromium alloy, high-nickel-chromium-molybdenum alloy and other high-quality materials are used. For example, Dalian Gaochang's corn tablet press rollers are cast using centrifugal composite casting equipment imported from Germany. The thickness of the alloy layer is 30-40 mm, which ensures the strength, wear resistance and corrosion resistance of the roller.

- Pattern shape: Common ones include corrugated, toothed, fish scale, etc. Different shapes of patterns are suitable for different corn flaking needs, such as corrugated rollers are suitable for grain steam humidification flaking.

Working principle of corn flaking pattern roller

After the corn kernels are fed into the pressing system through the feeding system, they are squeezed and kneaded between the relatively rotating patterned rollers. The presence of the pattern increases the friction and contact area, so that the corn kernels are evenly pressed into sheets with a certain thickness and shape.

Corn flaking pattern roller performance parameters

- Roller diameter and length: Common specifications include 500mm diameter and 1500mm length. There are also models with a roll length of 1.75 meters to meet different production requirements.

- Gap adjustment: The roller tightening operation is generally operated by hydraulic control. The roller gap is adjusted by adjusting the adjusting sleeve and the slider type fine adjustment device, which can achieve precise adjustment of the thickness of the corn embryo flakes during the production process. Generally, the corn can be pressed into a flake shape of 0.8mm-1.5mm.

Corn flaking pattern roller application areas

It is mainly used in corn flake production lines to process feed for livestock such as cattle and sheep, and to make breakfast cereal corn flakes and other foods.

Corn flaking pattern roller maintenance

- Regular cleaning: clean the residual corn residue, dust, etc. on the roller surface to prevent accumulation from affecting the quality of tableting and roller performance.

- Check wear: regularly check the wear of the pattern roller, especially the wear degree of the pattern. When the wear reaches a certain degree, it needs to be replaced or repaired in time to ensure the tableting effect.

- Lubrication and rust prevention: lubricate the roller shaft and other parts regularly to prevent rust and wear and extend the service life of the equipment.