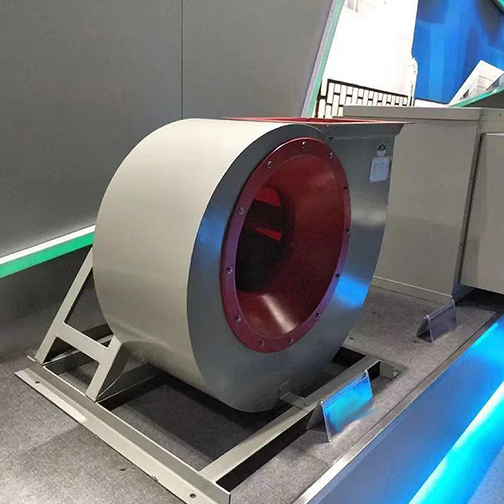

Centrifugal air conveyor

First, the corn flake centrifugal air conveyor has high conveying efficiency and can quickly transport corn flakes to the designated location, which can meet the needs of large-scale production;

Secondly, the damage to the material is small. The process of corn flake centrifugal air conveyor is relatively gentle, which can better maintain the integrity of corn flakes and reduce breakage.

Thirdly, the corn flaking centrifugal air conveyor equipment occupies a small area and has a relatively compact structure, which facilitates reasonable layout in a limited space; fourthly, it has good sealing performance, which can effectively prevent material leakage and reduce dust flying, thus ensuring a clean production environment and preventing material loss.

- The corn flaking centrifugal air conveyor has a high degree of automation: it can be linked with other production equipment to achieve automatic transportation, reduce manual intervention, and improve production efficiency and management level.

- The corn flaking centrifugal air conveyor is highly flexible: it can flexibly adjust the conveying route and direction according to the layout of the production workshop and the process requirements to adapt to different production environments.

- The corn flake centrifugal air conveyor has a wide range of material adaptability: it is not only suitable for corn flakes, but also has a good conveying effect on other granular and flaky materials with similar shapes and characteristics.

- The maintenance cost of the corn flaking centrifugal air conveyor is low: the structure is relatively simple, with few wearing parts, and daily maintenance is convenient, which reduces maintenance costs and downtime.

- Corn flaking centrifugal air conveyor is environmentally friendly and energy-saving: it adopts closed conveying to reduce dust emissions and meet environmental protection requirements; at the same time, the design of the centrifugal fan makes the energy consumption relatively low and has a certain energy-saving effect.

How it works

The corn flake centrifugal air conveyor uses the airflow generated by the fan to suspend the corn flakes in the airflow or transport them in groups along the pipeline in a closed conveying pipeline, relying on the kinetic energy and pressure energy of the airflow to transport the corn flakes from the starting point to the destination.

Corn flaking centrifugal air conveyor structure

- Feeding device: responsible for feeding corn flakes into the air conveying system evenly and stably.

- Centrifugal fan: generates strong airflow to provide power for the conveying of corn flakes.

- Conveying pipeline: It is usually made of wear-resistant and corrosion-resistant materials to ensure that the corn flakes are not damaged during transportation and can operate stably for a long time.

- Separation device: At the end of the conveying or the required position, the corn flakes are separated from the air flow, so that the corn flakes fall accurately into the designated receiving container or the next process equipment.

- Control system: It can realize precise control of the start, stop, conveying speed and other parameters of the air conveyor, and can also be linked with other production equipment to realize automated production.

Corn flaking centrifugal air conveyor performance parameters

- Conveying capacity: Depending on the model and configuration, it can convey several tons to dozens of tons of corn flakes per hour.

- Conveying distance: The horizontal conveying distance can reach tens of meters or even hundreds of meters, and the vertical conveying height can also meet the requirements of general production workshops.

- Conveying speed: By adjusting the speed of the fan or the parameters of the control system, the conveying speed of the corn flakes can be flexibly adjusted.

Application scenarios of corn flaking centrifugal air conveyor

It is mainly used in the workshops of corn flake production enterprises to transport the pressed corn flakes to subsequent processing equipment such as dryers and packaging machines. It can also be used for material handling between warehouses.

Corn flaking centrifugal air conveyor material selection

Parts in contact with corn flakes, such as conveying pipes and feeding devices, are generally made of food-grade stainless steel, which meets food hygiene standards and ensures that corn flakes are not contaminated. The impeller and casing of the fan are usually made of wear-resistant materials such as Q235 steel plates, and are made through processes such as laser welding to ensure the strength and stability of the equipment.