Pneumatic conveying pump

Efficient conveying: The corn flake pneumatic conveying pump can convey corn flakes at a higher speed, which can achieve continuous and stable material transportation and improve production efficiency.

Protect materials: The corn flakes are less damaged by the pneumatic conveying pump during transportation, and can better maintain their shape and integrity.

The corn flake pneumatic conveying pump can be flexibly laid out: the conveying pipeline can be flexibly laid according to the actual layout of the production workshop, and can realize horizontal, vertical or inclined conveying and adapt to different production environments.

Environmentally friendly and clean: The corn flake pneumatic conveying pump adopts sealed conveying, which effectively avoids dust leakage, reduces environmental pollution and improves the working environment.

High degree of automation: The corn flake pneumatic conveying pump can be linked with other production equipment to achieve automated operation through the control system, reducing manual labor intensity and improving production stability and reliability.

Easy maintenance: The structure of the corn flake pneumatic conveying pump is relatively simple, without complicated transmission parts, few wearing parts, relatively less daily maintenance work, and low maintenance cost.

Strong material adaptability: The corn flake pneumatic conveying pump is not only suitable for corn flakes, but also has a good conveying effect on other similar granular and flaky materials, and has strong versatility.

Working principle of corn flake pneumatic conveying pump

Based on aerodynamics, compressed air or other gases are used to generate airflow, so that corn flake particles are suspended in the airflow or transported in groups along the pipeline. In pressure transportation, high-pressure gas pushes the material to flow along the pipeline; in vacuum transportation, the negative pressure environment in the pipeline sucks the material and transports it to the target location.

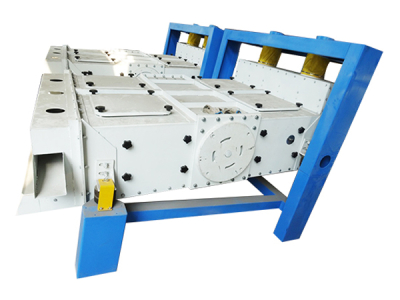

Structural composition

The corn flake pneumatic conveying pump is mainly composed of control system, conveying pipeline system, air source system, feeding system, dust removal system, etc. The control system is used to control the operation of the equipment; the conveying pipeline system is the conveying channel for materials; the air source system provides the power airflow; the feeding system is responsible for delivering the corn flakes into the conveying pipeline; the dust removal system is used to purify the tail gas and reduce dust emissions.

Corn flake pneumatic conveying pump performance parameters

- Conveying capacity: typically 1 - 50 t/h, depending on equipment model and configuration.

- Conveying distance: Horizontal conveying distance can reach 300 meters, and lifting height can reach 40 meters.

- Applicable materials: Mainly used for conveying dry powder materials such as corn flakes with a specific gravity below 2.0 and a moisture content below 5%.

Corn flake pneumatic conveying pump product features

- Environmentally friendly and clean: The transportation process is carried out in a closed pipeline, which can effectively prevent dust flying and leakage and reduce environmental pollution.

- Flexible layout: Pipelines can be laid flexibly according to the layout of the production workshop, and can achieve transportation in multiple directions such as vertical, horizontal or inclined.

- High efficiency and energy saving: It uses air flow for transportation, has high operating efficiency, is not prone to agglomeration or clogging, and can reduce energy consumption and maintenance costs.