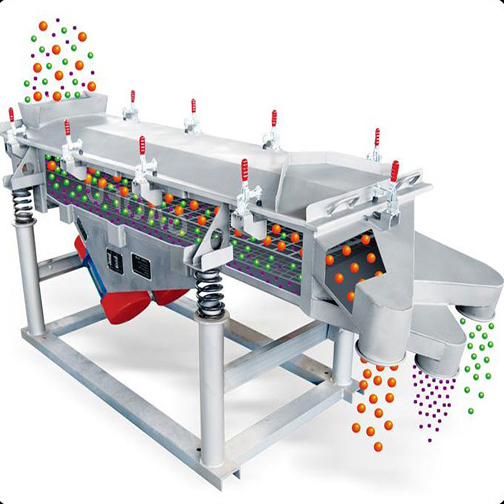

Linear vibrating screen

- Corn flake linear vibrating screen can screen efficiently: the linear vibration method makes the material do linear jumping motion on the screen surface, can pass through the screen quickly, has a large processing capacity and high screening efficiency, and can meet the screening needs in large-scale corn flake production.

- Corn flake linear vibrating screen has high precision: according to the different particle size requirements of corn flakes, the screen with appropriate mesh size can be selected to achieve accurate classification, effectively separate corn flakes of different specifications, and ensure the consistency of product quality.

- The corn flake linear vibrating screen operates stably: it is driven by dual vibration motors. By adjusting the exciting force and installation angle of the motors, the screen body can maintain stable linear vibration. The equipment runs smoothly and has high reliability, reducing equipment failures and maintenance costs caused by unstable vibration.

- Corn flake linear vibrating screen is easy to maintain: the structure is relatively simple, and the main components such as screen and vibration motor are easy to disassemble and replace. If the screen is worn or blocked after long-term use, it can be quickly cleaned or replaced, and the maintenance of the vibration motor is also relatively convenient, which reduces the maintenance difficulty and downtime of the equipment.

- Corn flake linear vibrating screen is environmentally friendly and energy-saving: The fully enclosed structure design effectively prevents dust from flying during corn flake screening, reduces environmental pollution, and improves the working environment. At the same time, the linear vibrating screen has low energy consumption, which reduces energy consumption and saves production costs while ensuring efficient screening.

The structure of corn flake linear vibrating screen

- Screen box: usually welded from steel plates of varying thicknesses, with sufficient strength and rigidity to withstand vibration and material impact.

- Screen frame: It is generally made of pine or other wood with less deformation. Its main function is to fix the screen, maintain the flatness of the screen, and ensure the screening effect.

- Screen: Mostly made of low carbon steel, stainless steel wire and other materials, with good wear resistance and corrosion resistance. The number of screen mesh can be selected according to the corn flake particle size requirements.

- Vibration motor: provides power for the screen machine, generates exciting force through the eccentric block, and makes the screen box vibrate.

- Motor base: used to install the vibration motor and transmit the power of the vibration motor to the screen box.

- Vibration-damping spring: installed between the screen box and the bracket, it plays a role of buffering and vibration reduction, reducing the impact of vibration on the ground and other equipment.

- Bracket: It is composed of pillars and channel steel, used to support the screen box and ensure the stability of the screen machine.

Working principle of corn flake linear vibrating screen

Driven by dual vibration motors, when the two motors rotate synchronously in opposite directions, the exciting forces generated by the eccentric blocks offset each other in the direction parallel to the motor axis, and are superimposed as a resultant force in the vertical direction, causing the screen to move in a straight line. The two motor shafts have an inclination relative to the screen surface. Under the action of the exciting force and the gravity of the material, the material is thrown up on the screen surface to make a jumping straight line motion, thereby achieving screening.

Technical parameters of corn flake linear vibrating screen

- Screen surface specifications: Common ones are 3700×1200mm, 4300×1400mm, 4800×1800mm, 6000×1800mm, etc.

- Feed particle size: generally less than or equal to 300mm.

- Processing capacity: Depending on the specifications of the screen surface, the processing capacity ranges from 10 to 600 tons/hour.

- Motor power: varies according to the equipment model and screen size, such as 0.37KW/unit × 2 units, 2.2Kw, etc.

Performance characteristics of corn flake linear vibrating screen

- High screening accuracy: can effectively separate corn flakes of different particle sizes to ensure product quality consistency.

- Large processing capacity: It can meet the screening needs in large-scale corn flake production and improve production efficiency.

- Stable operation: Driven by dual vibration motors, the screen body vibrates smoothly in a linear manner, with high reliability, reducing equipment failures and maintenance costs.

Application scope of corn flake linear vibrating screen

It is suitable for screening of non-sticky corn flakes with a particle size of 0.074-5mm, a water content of less than 70%, and can also be used for liquid filtration and screening operations such as sewage treatment. It can also handle larger particles of coal powder materials. Different needs can be met by thickening the screen body, increasing the motor power, and replacing the perforated screen plate.