Manual tablet press

- Low cost: Compared with electric tablet presses, manual corn tablet presses do not require an electric drive system and do not have complex automatic control devices. They have a simple structure, low manufacturing cost and affordable purchase price. They are an economical choice for small businesses, home workshops or individual users with limited budgets.

- Simple operation: The operation of the corn tableting machine is relatively simple and does not require professional technical training. Users only need to manually operate the pressing rod or handle to complete the corn tableting process, which requires low skills of the operator.

- Easy maintenance: Since the structure of the manual corn tablet press is relatively simple and the number of parts is small, maintenance and maintenance work is relatively easy. Users can clean, lubricate and perform simple repairs on the equipment by themselves without relying on professional maintenance personnel, reducing maintenance costs and downtime.

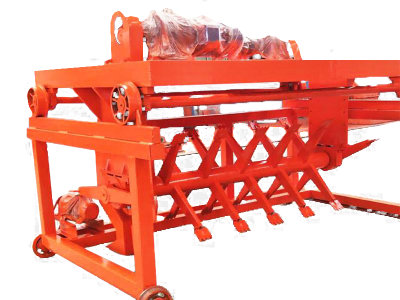

- High flexibility: The manual corn flake press is small in size and light in weight, easy to move and install, and users can adjust the position of the equipment at any time according to actual needs. At the same time, manual operation can flexibly control the pressure and flake speed according to different corn varieties, humidity and flake requirements to produce corn flakes that meet specific needs.

- Good safety performance: The manual corn tablet press does not have a complex electrical system and high-speed running parts, and will not cause safety hazards such as electric shock and mechanical injury during operation. Users can perform corn tableting operations in a relatively safe environment, which is especially suitable for use in some places with high safety requirements.

Working principle of corn tablet press

By manually operating the pressing rod or handle, the sheet pressing mechanism is driven to apply pressure to the corn placed in the mold, so that the corn is pressed into sheets under the pressure.

Corn tablet press manual tablet press product features

- Easy to operate: No complicated electrical control and professional skills are required, the tableting process can be completed through simple manual operation.

- Low cost: There is no electric drive system and automation device, the price is relatively low, suitable for users with limited budget.

- Easy maintenance: With simple structure and few parts, users can clean, lubricate and perform simple repairs by themselves, which reduces maintenance costs.

- Flexible and controllable: The pressure and speed of the tableting can be manually controlled according to needs, and the thickness, density and other parameters of the corn flakes can be flexibly adjusted.

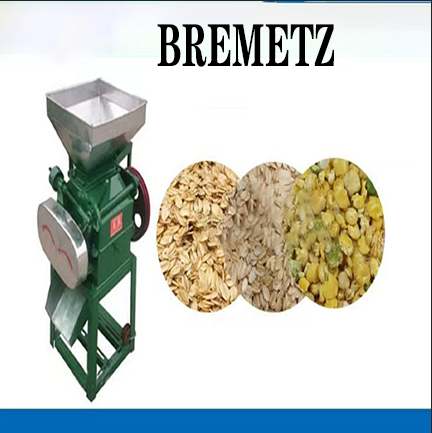

Corn tablet press manual tablet press main parts

- Tablet pressing mould: usually made of high-quality steel, with different specifications and shapes to meet the size and shape requirements of different corn flakes.

- Manual operating mechanism: including pressing rods, handles, etc., which use human power to drive the tableting die to press the corn.

- Feed device: usually a simple funnel or hopper, used to guide the corn material into the flaking die.

Corn tablet press manual tablet press technical parameters

- Maximum tableting pressure: generally around 5 - 15kN, the specific value depends on the tablet press model.

- Flake size: Common corn flake diameters range from 10 to 50 mm, and thickness can be adjusted from 1 to 5 mm.

- Production capacity: Due to the limited speed of manual operation, the output per hour is usually around 5 - 20kg.

- Equipment weight: The weight of the whole machine is generally around 50-100kg, which is easy to move and place.

Corn tablet press manual tablet press applicable scenarios

It is mainly suitable for small-batch corn flake production in small farms, family workshops, laboratories, etc. It can also be used by individuals for small-scale processing of corn flakes.