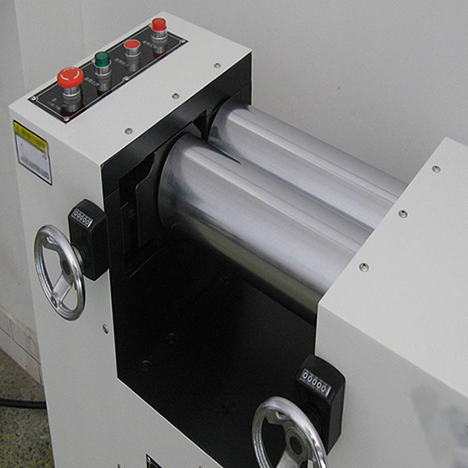

Double roller tablet press

- Efficient and continuous production: The corn flaking double roller flaking machine continuously extrude corn through two relatively rotating rollers, which can achieve high production efficiency and is suitable for large-scale production.

- Good flake quality: The corn flake double roller flake press can accurately control the thickness, density and uniformity of corn flakes by adjusting parameters such as roller spacing, speed and pressure, and produce corn flakes with stable quality and consistent taste.

- Strong adaptability: It can adapt to corns of different varieties and humidity. By adjusting the process parameters, it can flake various corn raw materials to meet the needs of different users.

- Corn flaking double roller flaking machine has high degree of automation: equipped with advanced control system, it can realize automatic operation, reduce manual intervention, improve production efficiency and product quality stability, and reduce labor intensity.

- Long service life: Using high-quality materials and advanced manufacturing technology, the key components of the corn flaking double roller flaking machine have high wear resistance and corrosion resistance, can operate stably for a long time, and reduce the maintenance cost and replacement frequency of the equipment.

How it works

The corn enters the corn flaking double roller flaking machine through the feed hopper. Two relatively rotating rollers exert pressure on the corn. Under the extrusion action, the corn is pressed into flakes and discharged from the gap between the two rollers.

Corn flaking double roller flaking machine product features

- Good flake pressing effect: The thickness, density and uniformity of corn flakes can be precisely controlled by adjusting parameters such as roller spacing.

- Wide application range: can process corn, sorghum, wheat, beans and other grains.

- Strong durability: The rollers are usually made of high-quality materials such as hard manganese steel, which has good wear resistance and corrosion resistance and long service life.

Corn flaking double roller flaking machine main parts

- Pressing roller: It is the core component, generally made of carbide or special steel, and the surface is treated to ensure the quality of corn flakes and the life of the pressing roller.

- Drive system: including motor, reducer, belt or gear transmission device, etc., which provides power for the pressure roller to ensure its stable and precise operation.

- Feeding device: It is composed of a feeding hopper, a feeding adjustment mechanism, etc., which controls the feeding speed and flow rate of corn to ensure that the material enters the pressing roller evenly.

Adjustment mechanism: used to adjust the spacing, pressure and other parameters of the pressing rollers to adapt to different corn varieties and flaking requirements.

Corn Flake Double Roller Flake Press Technical Parameters

- Output: Small equipment may produce around 150 - 400 kg per hour, and large equipment can produce higher output.

- Power: Small equipment generally has a power of 2.2 - 3kW, while large equipment can reach tens of kilowatts.

- Roller size: A small tablet press may have a roller diameter of 100-200mm and a length of 200-300mm; a large tablet press will have a larger roller diameter and length.

- Tablet thickness: usually adjustable within the range of 1 - 5 mm.

Corn flaking double roller flaking machine application scenarios

It is widely used in grain processing plants, farms, food factories, etc. In grain processing plants, it is used for large-scale corn flake production; in farms, it is used to process corn flakes as livestock feed to improve feed utilization; in food factories, it is used to produce instant corn flakes and other foods.