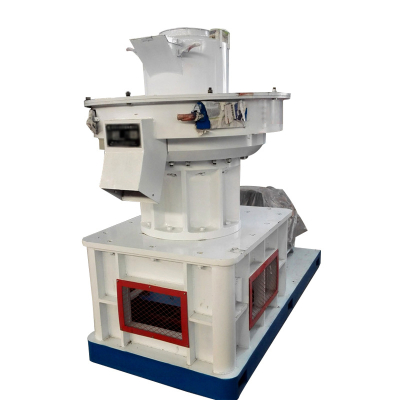

Electric tablet press

Efficiency

- Electric drive, high degree of automation, the corn tablet press electric tablet press can press corn into tablets continuously and quickly, the production efficiency is greatly improved compared with the manual tablet press, and it is suitable for large-scale production.

Uniform and stable pressure

- Equipped with advanced pressure control system, the corn tablet press can accurately adjust and control the pressure to make the density and hardness of corn tablets uniform and ensure stable product quality.

- Corn tablet press electric tablet press usually has a user-friendly operation interface, and the staff can easily get started after simple training, which reduces the difficulty of operation and labor intensity.

High security

- The corn flaking electric tablet press is equipped with multiple safety protection devices, such as overload protection, emergency brake button, etc., which can effectively prevent accidents and ensure the safety of operators.

Easy to clean and maintain

- The structure is designed reasonably, easy to disassemble and assemble, convenient for cleaning and maintenance of various parts of the corn tablet press, reducing downtime and improving equipment utilization.

Wide range of applications

- The corn tableting electric tableting machine is not only suitable for corn tableting, but also can tablet other similar materials according to different molds and process requirements. It has strong versatility and flexibility.

Corn tablet press electric tablet press product features

- High degree of automation: With just one button, the whole process from corn feeding to tableting can be realized without frequent manual intervention.

- Easy to adjust: The roller gap can be controlled by a worm or online adjustment device, the minimum can be 1mm, and the thickness of the corn flakes can be accurately adjusted.

- Wide range of material processing: In addition to corn, it can also flak sorghum, wheat, beans and other grains.

- Good safety performance: Some electric corn flaking machines are equipped with magnetic separation devices to prevent iron filings from damaging the rollers, and are also equipped with steam removal devices to prevent steam from corroding the factory building.

- Excellent product quality: Through precise pressure and temperature control, each kernel of corn is evenly crushed, and the corn flakes produced have uniform thickness and density.

Working principle of corn tablet press

After cleaning and screening, the raw corn enters the soaking stage, where it is adjusted to the appropriate moisture and gelatinization degree, and then enters the tablet press. The rollers or dies of the tablet press are electrically driven to apply pressure to the corn, pressing it into sheets, which are finally discharged through the discharging device.

Corn tablet press electric tablet press main parts

- Power system: Generally, electric motors are used. The power varies according to the tablet press model and output. For example, the common power of a 1.5-ton single-punch tablet press is 250 watts, and the power of a large tablet press can reach 18.5 kW or even higher.

- Flaking mechanism: such as the hard manganese steel rollers of the roller flaking machine, or the punch of the single punch flaking machine, which are the components that directly flake the corn.

- Adjustment device: including mechanisms for adjusting roller gap or die pressure, filling depth, tablet thickness, such as screw handles, worm gears, etc.

- Feeding and discharging devices: The feed hopper is used to feed corn materials, and the discharging port discharges the pressed corn flakes. Some are also equipped with a conveyor belt to ensure that the corn flakes are discharged smoothly and are not deformed by external forces.

Corn tablet press electric tablet press technical parameters

- Model: such as 12-20, 17-28, 17-40, etc.

- Supporting power: There are different specifications such as 2.2kw (220v), 3kw (380v), etc.

- Rated speed: usually in the range of 360-420r/min.

- Output: Taking the 12-20 model as an example, the flattening output is 300-450kg/h, and the crushing output is 800-1000kg/h.

Corn tablet press electric tablet press applicable scenarios

It is widely used in major wineries, grain processing plants, food processing plants, farms and other fields. It is suitable for large-scale corn flake production, and can also be used for small-batch processing in small enterprises or family workshops.