Tank fermentation tank

- Large processing capacity: Organic fertilizer tank fermentation tanks are usually large in size and can accommodate a large amount of organic materials for fermentation. They are suitable for large-scale organic fertilizer production and can meet the needs of large farms, agricultural waste treatment centers and other places.

- The organic fertilizer trough fermentation tank has good fermentation effect: the material is turned over regularly through the turning device, so that the material is fully in contact with the air, ensuring the supply of oxygen, which is conducive to the growth and reproduction of aerobic microorganisms, promoting the rapid decomposition and maturity of organic matter, and improving the fermentation efficiency and quality.

- Low equipment cost: Compared with some other fermentation equipment such as tower fermentation tanks, the structure of organic fertilizer tank fermentation tanks is relatively simple. It is mainly composed of a tank body, a turning device and a ventilation system. The manufacturing and installation costs are relatively low, and the investment is small. It is suitable for small and medium-sized enterprises and individual producers.

- Easy operation and maintenance: Its operation is relatively simple. The operation of the turning device and the control of the ventilation system are easy to master. Daily maintenance mainly involves equipment inspection, lubrication and replacement of wearing parts. The maintenance cost is low and the technical requirements for operators are not high.

- Organic fertilizer trough fermentation tank has strong adaptability: it can process a variety of organic waste, such as livestock and poultry manure, crop straw, kitchen waste, etc. It has good adaptability to the properties and composition of different materials, and can adjust the fermentation process parameters according to actual conditions to realize the resource utilization of waste.

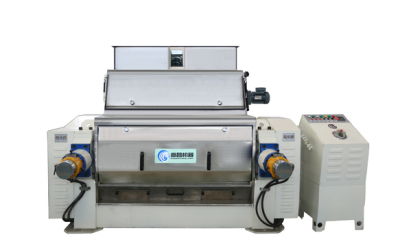

Organic fertilizer tank fermentation tank structure

- Tank: Usually made of concrete or steel structure, it has a certain length, width and depth to accommodate the fermented materials. The bottom of the tank is sloped to facilitate drainage and discharge.

- Turning device: It is composed of motor, reducer, transmission shaft, turning blades, etc. It can turn the materials regularly to make the materials fully contact with air and promote fermentation.

- Organic fertilizer tank fermentation tank ventilation system: including fans, ventilation ducts, etc. The fan sends air into the ventilation duct at the bottom of the tank, and then the small holes on the duct evenly distribute the air to the material, providing sufficient oxygen for aerobic microorganisms.

- Control system: It can realize automatic control of the operating time and frequency of the turning device, as well as the air volume, air pressure and other parameters of the ventilation system, and can also monitor the temperature, humidity and other data during the fermentation process.

Working principle of organic fertilizer tank fermentation tank

Aerobic microorganisms are used to decompose organic matter in organic waste into stable humus. During the fermentation process, the turning device and ventilation system provide microorganisms with suitable oxygen, temperature, humidity and other conditions, which promote the growth and reproduction of microorganisms, accelerate the ripening and decomposition of organic matter, and kill harmful bacteria, insect eggs and weed seeds.

Product features of organic fertilizer tank fermentation tank

- Large processing capacity: It can process a variety of organic wastes, such as livestock and poultry manure, crop straw, kitchen waste, etc., and is suitable for large-scale organic fertilizer production.

- Good fermentation effect: Through turning and ventilation, the material can be fermented evenly, which can effectively shorten the fermentation cycle and improve the fermentation efficiency and quality.

- Organic fertilizer tank fermentation equipment has low cost: compared with some other types of fermentation equipment, it has a simpler structure and relatively low investment cost.

- Easy operation and maintenance: The operation is relatively easy. Daily maintenance mainly involves equipment inspection, lubrication and replacement of wearing parts, etc., and the maintenance cost is low.

Application scope of organic fertilizer tank fermentation tank

It is widely used in livestock and poultry farms, agricultural waste treatment centers, urban sewage treatment plants, organic fertilizer production enterprises, etc. It can harmlessly treat and recycle organic waste such as livestock and poultry manure, crop straw, urban sludge, and kitchen waste.