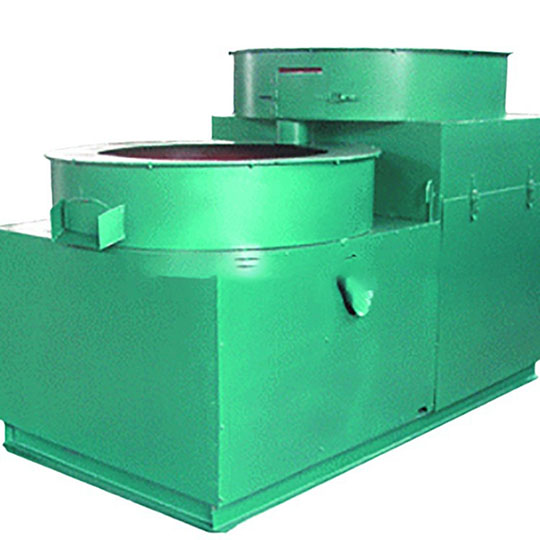

Fully automatic rounding machine

Advantages of the two-stage rounding machine for organic fertilizer granules:

1.The two-stage rounding machine for organic fertilizer granules has high output and flexible process layout. It can be used simultaneously with the organic fertilizer granulator, disc granulator, and flat film extrusion granulator, solving the disadvantages of complex process, large equipment investment, and unstable finished product quality caused by the need for a single granulator to be equipped with a rounding machine;

2. The two-stage rounding machine for organic fertilizer granules consists of two or three rounding cylinders arranged in sequence. After the material is rounded several times, the finished product is discharged from the discharge port. The finished product has uniform particle size, is round and smooth, and the finished product rate is as high as 97%. A small amount of fertilizer falls from the gap on the edge of the disc of the organic fertilizer rounding machine and flows out along the discharge port.

3. The organic fertilizer granule two-stage rounding machine has beautiful appearance, simple structure and working principle, safe and reliable, small size, light weight, easy operation and maintenance;

4. The machine has the ability to adapt to various working environments. The organic fertilizer granule two-stage rounding machine can maintain long-term continuous operation, low power consumption, low electricity consumption, low production cost and high economic benefits.

Working principle of organic fertilizer granule two-stage rounding machine:

Organic fertilizer such as chicken manure is first ground into cakes by a flat film granulator with a roller, and then cut into cylindrical particles by knife extrusion, and then enters the organic fertilizer granule two-stage rounding machine for rounding.

The organic fertilizer granule two-stage rounding machine is a layered continuous organic fertilizer granule polishing and granulation equipment. A large cylinder is fixed at the bottom of the Saudi, and the upper end of the large cylinder is connected to the upper cover, and a feed trough is provided on the upper cover. The textile vertical shaft is connected to the sludge through a double self-aligning ball bearing, and the lower end of the vertical shaft is connected to the motor output shaft through a spray mechanism. The upper part of the vertical shaft extends into the interior of the large cylinder and is fixedly connected to the large turntable.

The outer edge of the large turntable is connected to the inner wall of the large cylinder through sliding contact. The large turntable is connected to the circular overflow port of the large cylinder, and the bottom of the large turntable is connected to the discharge chute: its vertical axis is connected to the extension axis, and the extension axis is fixedly connected to at least one small turntable concentric with the large turntable.

The small turntable is located above the large cylinder, and the outer edge of each small turntable is connected to the inner wall of the small cylinder through sliding contact. The upper end of the small cylinder is fixedly connected to the upper cover, and a small cylinder overflow port is opened on the wall of the small cylinder. The fermented raw materials do not need to be dried and can be directly made into spherical granular organic fertilizer, which greatly reduces manual labor.

Product features of organic fertilizer granule two-stage rounding machine:

1. High output, flexible process layout, can be used with one or more granulators at the same time, solving the problems of complex process, large equipment investment, and uneven quality of finished products caused by the need for granulators to be equipped with rounding machines in the past.

2. The organic fertilizer granule double-stage rounding machine is composed of two or more cylinders arranged in sequence. The material is discharged from the discharge port after multiple rounding. The finished granules have uniform particle size, high density, roundness and smoothness, and high output.