Fully automatic double shaft wet mixer

The fully automatic inorganic fertilizer double-shaft wet mixer has the following advantages:

- High mixing uniformity: The double-shaft structure enables the materials to form a complex cross-flow during the mixing process, and the materials at different positions can be fully mixed, effectively ensuring the uniform distribution of the components of the compound fertilizer and improving the stability of product quality.

- Strong material adaptability: It can handle a variety of materials of different properties. For materials with high viscosity and high humidity, the fully automatic inorganic fertilizer double-shaft wet mixer can achieve a good mixing effect of the materials with its powerful mixing ability, meeting the production needs of different compound fertilizer formulas.

- High mixing efficiency: The two mixing shafts work at the same time. Compared with the single-shaft mixer, it can handle more materials in the same time, improve production efficiency, and meet the requirements of large-scale compound fertilizer production.

- Stable equipment operation: The fully automatic inorganic fertilizer double-shaft wet mixer adopts high-quality transmission components and reasonable structural design, and the equipment runs smoothly with less vibration and noise. This is not only conducive to extending the service life of the equipment, but also creates a relatively good working environment for operators.

- Good sealing: Good sealing design effectively prevents material leakage and dust flying, reduces material loss, and also avoids pollution to the production environment, meeting the requirements of environmental protection and safe production.

Structural composition of fully automatic inorganic fertilizer double-shaft wet mixer

- Mixing shaft: usually two parallel shafts, made of high-strength alloy steel or carbon steel, which can withstand large torque and bending moment.

- Mixing blade: installed on the mixing shaft, with various shapes and sizes, common ones are spiral blades, paddle blades, etc., generally made of wear-resistant materials such as hard alloy or specially treated steel.

- Casing: welded with steel plates, usually lined with wear-resistant rubber or ceramics to improve wear resistance and corrosion resistance, with feed and discharge ports at both ends.

- Driving device: including motor, reducer, coupling, etc., to provide power for the mixing shaft, so that the two mixing shafts can rotate synchronously and stably.

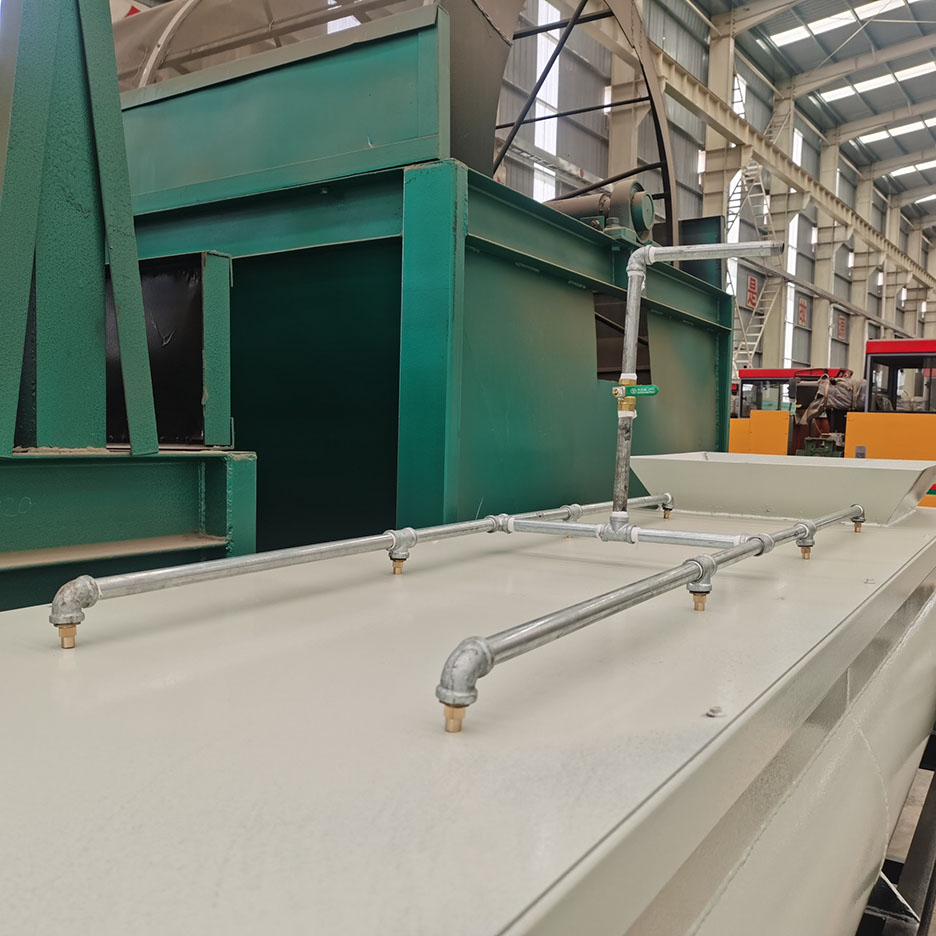

- Water spraying device: located at the top of the mixer or near the feed port, composed of nozzles, water pipes and valves, etc., can accurately control the amount of water sprayed to make the material reach the appropriate humidity.

Working principle of fully automatic inorganic fertilizer double-shaft wet mixer

The two mixing shafts rotate in opposite directions under the drive device, and the mixing blades push the material to make complex three-dimensional movements in the mixing chamber. The material enters from the feed port. Under the action of the mixing blades, it flows along the axial direction on the one hand, and crosses and mixes between the two shafts on the other hand. At the same time, the water spraying device evenly sprays an appropriate amount of water into the material, so that the material and water are fully in contact and mixed evenly, and are discharged from the discharge port after reaching the set humidity requirements.

Performance characteristics of fully automatic inorganic fertilizer double-shaft wet mixer

- Efficient mixing: The double-shaft structure and unique blade design enable the materials to be evenly mixed in a short time, and the mixing efficiency is 30% - 50% higher than that of the single-shaft mixer.

- High mixing intensity: It can produce strong shearing, extrusion and kneading effects, and can handle high-viscosity and high-humidity materials such as sludge and clay.

- Strong adaptability: By adjusting the mixing shaft speed, blade angle and water spray parameters, it can adapt to the mixing needs of different materials and is widely used in chemical, building materials, environmental protection and other industries.

- Good sealing: The use of sealed bearings and sealing covers can effectively prevent material leakage and dust flying, improve the working environment, and reduce material waste.

- Before starting the fully automatic inorganic fertilizer double-shaft wet mixer: check whether the connection of each component is firm, whether the mixing shaft rotates flexibly, whether the lubrication and sealing are good, whether the electrical system is normal, and then turn on the water spray device for debugging to ensure uniform water spray.

- During operation: first start the equipment to run at no load for a few minutes, then slowly feed the material, and adjust the water spray amount according to the material humidity. Closely observe the operation status of the equipment. If there is any abnormality, stop the equipment in time.

- After shutdown: first stop feeding, let the equipment continue to run until the material is emptied, turn off the power, clean up the residual material inside and outside the equipment, and regularly conduct a comprehensive inspection and maintenance of the equipment.

Maintenance of fully automatic inorganic fertilizer double-shaft wet mixer

- Regular inspection: Check the wear of the mixing shaft and blades at least once a week, check the operating conditions of the reducer and motor every month, and check the sealing of the sealing parts every quarter.

- Timely replacement: If the wear of the mixing shaft and blades exceeds the specified limit, or the sealing parts leak, they should be replaced in time.

- Lubrication maintenance: According to the requirements of the equipment manual, regularly add or replace lubricating oil to the reducer, bearings and other parts to ensure good lubrication.

- Clean equipment: After each shutdown, clean up the material residue inside and outside the equipment in time to prevent material accumulation and corrosion.