Probability Screen

- High screening efficiency: The corn flake probability screen uses the probability screening principle. When the material moves on the screen surface, fine particles have more opportunities to pass through the screen holes. Compared with traditional screening methods, screening can be completed in a shorter time, greatly improving the processing volume per unit time.

- The corn flake probability screen has strong processing capacity: its unique screen surface structure and movement mode enable the material to disperse and flow quickly on the screen surface, which can adapt to the corn flake screening work with a larger flow rate and meet the needs of large-scale production.

- Long screen life: When the corn flaking probability screen is working, the contact between the material and the screen is relatively gentle, unlike some screening equipment with severe vibrations that cause strong impact on the screen, thereby effectively reducing the wear of the screen, extending the service life of the screen, and reducing the operating cost of the equipment.

- The corn flake probability screen has wide adaptability: it can adapt to the screening requirements of corn flakes with different particle size distributions by adjusting parameters such as the screen surface inclination angle and vibration frequency. Whether the corn flakes have large particle differences or are relatively uniform, they can be screened well.

- The corn flaking probability screen has a simple structure: the overall structure is relatively simple, without overly complicated parts, which not only facilitates the installation and commissioning of the equipment, but also makes it easier to operate in the later maintenance process, reducing the difficulty and cost of maintenance.

How it works

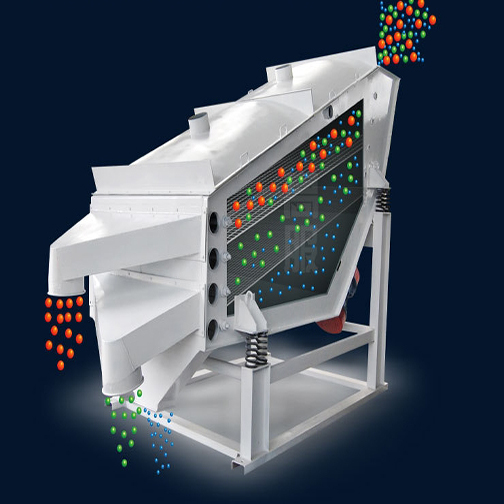

The corn flake probability screen works based on the probability screening principle. After the material is fed to the screen surface, the screen surface has a certain inclination and makes a specific movement, so the material jumps, slides and other motion states on the screen surface. Fine particles have a higher probability of passing through the screen holes due to their own gravity and inertia, thus achieving screening by particle size.

Corn flake probability screen structure composition

- Screen box: It is the main working part, usually made of high-quality steel, with sufficient strength and rigidity to carry the material screening process. Screens of different specifications are installed in the screen box.

- Vibrator: The vibration force is generated by the rotation of the eccentric block, which makes the screen box vibrate and causes the material to move on the screen surface. The vibrator is generally driven by a motor, and the vibration force can be adjusted by adjusting the angle of the eccentric block.

- Support device: Generally, elastic elements such as springs are used to support the screen box, which can not only ensure the normal vibration of the screen box under the action of exciting force, but also reduce the transmission of vibration to the foundation and reduce the impact on surrounding equipment and building structures.

- Feeding device: Located above the screen box, it is responsible for feeding corn flakes evenly onto the screen surface to ensure the continuity and stability of the screening process.

- Discharging device: located below the screen box, it is used to collect and discharge the sieved corn flakes of different particle sizes. Different discharging ports correspond to the products sieved by different screens.

Corn flake probability screen performance characteristics

- High screening efficiency: Using the principle of probability screening, fine particles have more chances to pass through the sieve holes, and the processing volume per unit time is high.

- Strong processing capacity: The unique structure enables the material to disperse and flow quickly, and can adapt to large-flow corn flake screening.

- Long screen life: The material contacts the screen gently, which reduces wear and tear and reduces operating costs.

Corn Flake Probability Screen Technical Parameters

- Screen surface specifications: Common screen surface lengths range from 2 to 5 meters, and widths range from 1 to 3 meters, depending on actual production needs.

- Vibration frequency: generally around 800 - 1500 times per minute, which can be changed by adjusting the motor speed or exciter parameters.

- Screen surface inclination: usually between 15° - 45°, different inclinations are suitable for different screening needs.

- Processing capacity: Small equipment may have an hourly processing capacity of 5-15 tons, and large equipment can reach more than 30 tons per hour, depending on factors such as screen size, vibration parameters, etc.