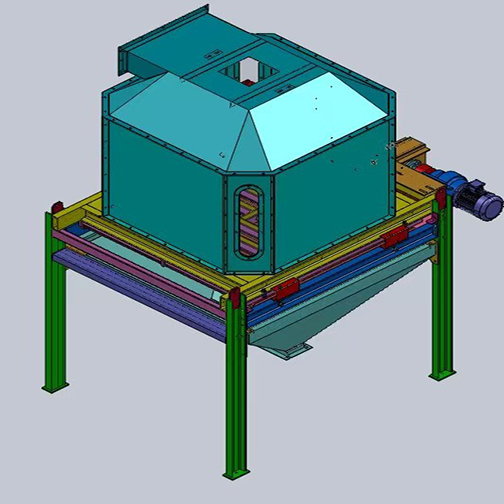

Counterflow cooler

- Good cooling effect: The countercurrent cooler for corn flakes adopts the countercurrent cooling principle. The corn flakes and the cold air flow in the cooler in the opposite direction, which can fully exchange heat, make the corn flakes cool evenly, and the temperature after cooling is closer to the ambient temperature, effectively ensuring the product quality.

- Energy saving and high efficiency: The countercurrent design enables the cold air to absorb the heat of the corn flakes to the maximum extent, improves the cooling efficiency, and under the same cooling effect, it can reduce the amount of cold air and reduce the energy consumption of the fan compared with other cooling methods, thereby achieving the purpose of energy saving.

- Drying function: During the cooling process, the countercurrent cooler for corn flakes can take away some moisture due to the full contact between the air and the corn flakes, which has a certain drying effect, helps to reduce the moisture content of the corn flakes and extend their shelf life.

- Compact structure: The countercurrent cooler for corn flakes has a relatively simple and compact structure, a small footprint, is easy to install and maintain, can effectively save production space, and is suitable for production enterprises of different sizes.

- High degree of automation: Corn flake countercurrent coolers are usually equipped with advanced control systems, which can realize functions such as automatic feeding, discharging, and cooling parameter adjustment, reduce manual operations, and improve production efficiency and product quality stability.

Working Principle

High-temperature corn flakes enter from the top of the corn flake counterflow cooler, and after being diverted by the closed air feeder and bulk feeder, they flow into the silo from the top of the silo in multiple ways. The fan allows natural air to enter from the bottom, pass through the material layer in the silo, and flow in the opposite direction of the corn flakes to exchange heat, take away heat and moisture, and play a role in cooling and reducing moisture.

Corn flake countercurrent cooler structure

- Feeding device: usually includes closed air feeder and diamond cone bulk feeder to prevent air leakage during feeding, so that corn flakes can be evenly diverted into the cooling bin.

- Cooling box: generally octagonal cross-section, which can reduce cooling dead angle and facilitate uniform cooling of materials.

- Discharging mechanism: common discharging structures include flap type, slide valve type and impeller type. For example, the flap type discharging mechanism moves smoothly and reliably, with small residue and no damage to the finished material.

- Transmission device: The eccentric shaft is driven by a reduction motor, which has stable and reliable transmission, low noise, and easy installation and maintenance.

- Suction system: The fan provides power to form a countercurrent of air to achieve cooling function, and the air volume can be adjusted to control the cooling effect.

Performance characteristics of corn flake countercurrent cooler

- Good cooling effect: using the countercurrent cooling principle to avoid direct contact between cold air and hot materials to produce sudden cooling, prevent the surface of corn flakes from cracking, and can cool corn flakes with a temperature of 70℃ - 90℃ to slightly higher than room temperature by 3℃ - 6℃.

- Drying function: during the cooling process, the moisture content of corn flakes can be reduced to a safe moisture content (less than or equal to 12.5%), which is convenient for transportation, storage and preservation.

- The corn flake countercurrent cooler operates stably: the discharge mechanism moves smoothly, with little residue, no damage to the corn flakes, and the overall operation of the equipment is reliable with a low failure rate.

- Easy operation: Equipped with an automated control system, it can realize automatic feeding, discharging and parameter adjustment, which is simple to operate and easy to maintain.

Corn flake countercurrent cooler application scope

Widely used in the cooling treatment of corn flakes and other pelletized feeds such as granulated feed and expanded feed in the feed industry.

Technical parameters

Different models of corn flake countercurrent coolers have different parameters such as production capacity and power. The production capacity is generally around 3 - 9m^{3}/p, and the applicable corn flake output range is relatively wide. The motor power is usually around 1 - 5kW, mainly used to drive the discharge mechanism and fan, etc. The temperature of the corn flakes after cooling is not higher than room temperature + 3℃ - 5℃, and the moisture can be reduced to a safe level.