Plane reciprocating screen

- The corn flakes flat reciprocating screen has high screening efficiency: through the flat reciprocating motion, the corn flakes can be evenly distributed on the screen surface and fully moved, increasing the contact opportunities between the material and the screen, thereby improving the screening efficiency and effectively separating corn flakes of different particle sizes.

- The corn flake flat reciprocating screen has a large processing capacity: its structural design and movement mode allow a large flow of corn flakes to pass through, which can meet the needs of large-scale production and adapt to higher-yield corn flake screening operations.

- The flat reciprocating screen for corn flakes is not easy to get clogged: the flat reciprocating motion makes the material constantly turn over on the screen surface, which is not easy to gather and accumulate, reducing the possibility of clogging of the screen holes. Even when processing corn flakes with high impurities, it can maintain a good screening effect.

- The corn flake flat reciprocating screen has strong adaptability: according to the different characteristics and screening requirements of corn flakes, the parameters such as the mesh size, movement amplitude and frequency of the screen can be flexibly adjusted to meet various screening needs. Whether it is coarse or fine corn flakes, it can effectively screen.

- The corn flaking flat reciprocating screen runs smoothly: it adopts a relatively stable transmission device and structural design, and generates less vibration and noise during operation, which not only reduces the wear of the equipment and prolongs its service life, but also creates a relatively quiet and comfortable working environment for the operators.

- The corn flaking flat reciprocating screen is easy to maintain: the equipment has a relatively simple structure, and the installation and disassembly of parts are relatively convenient, which is convenient for daily inspection, cleaning, maintenance and replacement of wearing parts, reducing maintenance costs and downtime, and is conducive to continuous production.

Working principle of corn flake flat reciprocating screen

The motor drives the eccentric shaft to rotate, and the pull rod converts the rotational motion of the eccentric shaft into reciprocating linear motion of the screen body. Then, the material is discharged from the screen holes in order from fine to coarse by utilizing the dead weight of the material and the installation inclination of the screen body, thereby achieving the purpose of screening the material.

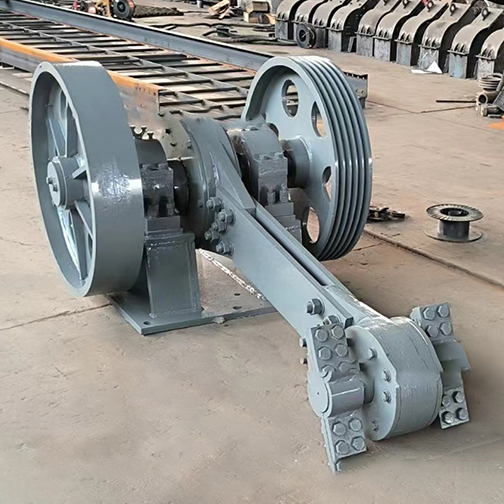

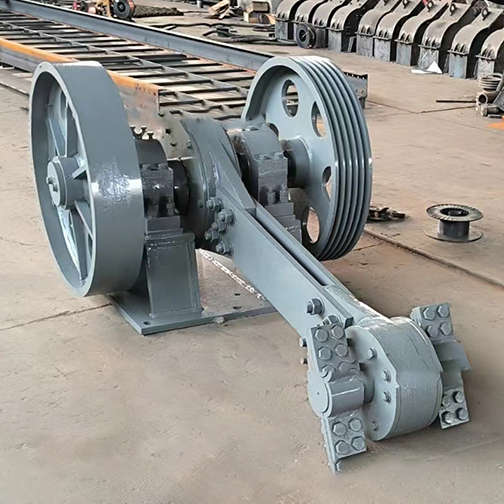

The structure of the corn flake flat reciprocating screen

- Screen body: It is the main working part of screening, usually made of steel plate or stainless steel plate, with certain strength and rigidity, able to withstand the impact and vibration of materials.

- Transmission device: It is generally composed of a motor, an eccentric shaft, a pull rod, etc. The motor provides power and converts the motor's rotational motion into reciprocating linear motion of the screen body through the eccentric shaft and the pull rod.

- Screen: It is the key component that determines the screening effect. According to different screening requirements, screens of different mesh sizes and materials can be selected, such as stainless steel screens, nylon screens, etc.

- Frame: used to support the screen body and transmission device to ensure the stability of the equipment. It is usually welded by channel steel, angle steel, etc.

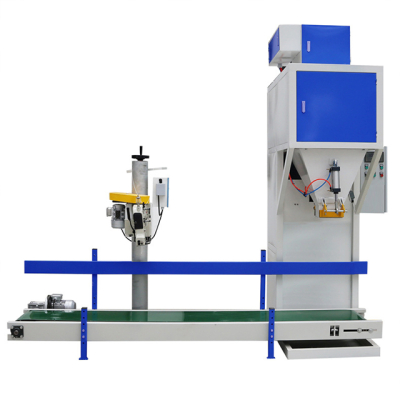

- Feeding device: Located above the screen body, it is used to feed the corn flakes evenly into the screen body to ensure the efficiency and effect of screening.

- Discharging device: located below the screen body, used to collect and discharge the sieved corn flakes, usually composed of a discharging port, a discharging chute, etc.

Performance characteristics of corn flake flat reciprocating screen

- High screening efficiency: Through the plane reciprocating motion, the material is evenly distributed on the screen surface and fully moves, increasing the chance of contact with the screen, and can effectively separate corn flakes of different particle sizes.

- Large processing capacity: The structural design and movement mode allow a large flow of corn flakes to pass through, which can meet the needs of large-scale production.

- Not easy to be blocked: the reciprocating motion of the plane makes the material constantly turn over, which is not easy to gather and accumulate, reducing the possibility of blockage of the screen hole.

Technical parameters of corn flake flat reciprocating screen

- Screen surface size: The screen surface size of common small equipment may be less than 1 meter x 1 meter, and the screen surface size of large equipment can reach more than 2 meters x 2 meters.

- Motor power: Generally between 0.55-5.5kW. Small equipment may use a 0.55-1.5kW motor, while large equipment requires a 3-5.5kW motor.

- Screening accuracy: can be adjusted according to needs, generally can reach ± 0.5 mm accuracy

- Processing capacity: Small equipment may process 1-5 tons per hour, medium-sized equipment may process 5-15 tons per hour, and large equipment may process more than 15 tons per hour.