Multi-roller tablet press

- Better flake quality: The corn flake multi-roller flaking machine uses multiple rollers to gradually extrude corn, which can more accurately control the thickness, density and uniformity of corn flakes, making the extruded corn flakes more delicate and uniform in thickness, thereby improving product quality.

- Higher production efficiency: Multiple rollers work together to process more corn raw materials per unit time, increasing production capacity. It is suitable for large-scale corn flake production and can meet the production needs of large grain processing plants, feed mills and other enterprises.

- Strong adaptability to raw materials: The corn flaking multi-roller flaking machine can adapt to corn raw materials of different varieties, humidity and hardness by adjusting parameters such as pressure, speed and spacing of different rollers. It can perform good flaking processing on all kinds of corn, reducing production problems caused by raw material differences.

- Good equipment stability: The multi-roller structure makes the pressure distribution more uniform, the equipment runs more smoothly, reduces the equipment vibration and wear caused by excessive pressure at a single point or uneven force, extends the service life of the equipment, and reduces maintenance costs.

- Product diversification: By changing the shape of the rollers, surface texture or adjusting the flaking process parameters, the corn flaking multi-roller flaking machine can produce corn flakes products of different shapes, specifications and tastes, meeting the market demand for diversified corn flakes products and improving the company's market competitiveness.

How it works

After the corn enters the corn flaking multi-roller flaking machine, it is gradually squeezed by multiple rollers. Multiple rollers cooperate with each other to continuously roll the corn through different speeds, pressures and spacing settings, so that the corn is pressed into flakes in the process of gradual force.

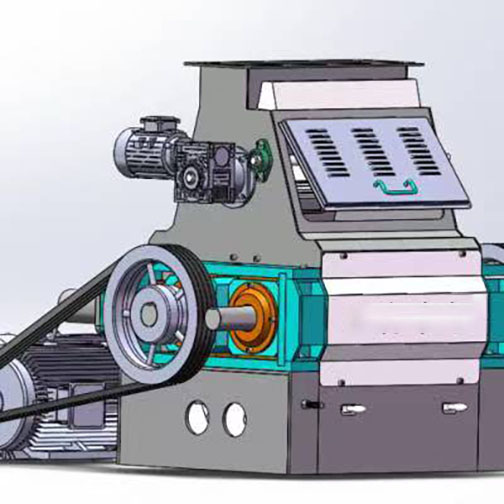

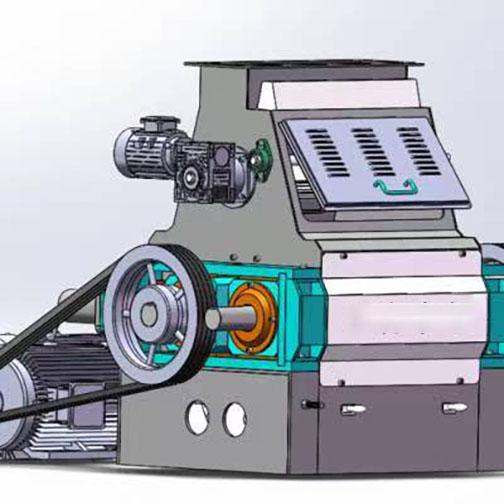

Corn flaking multi-roller flaking machine main parts

- Pressing roller: usually made of carbide or special steel, with surface treated, wear-resistant and able to ensure the quality of corn flakes.

- Drive system: including motor, reducer, belt or gear transmission device, etc., to provide power for the pressure roller to ensure stable operation.

- Feeding device of corn flaking multi-roller flaking machine: It consists of a feeding hopper, a feeding adjustment mechanism, etc., which controls the feeding speed and flow rate of corn to ensure that the material enters the pressing rollers evenly.

- Adjustment mechanism: used to adjust the spacing, pressure and other parameters of the pressing rollers to meet different tablet pressing requirements.

Corn flaking multi-roller flaking machine technical parameters

- Output: Varies depending on the equipment model and specifications. Small equipment may have an output of several hundred kilograms per hour, while large equipment can reach several tons or even higher.

- Power: The power of small equipment may range from several kilowatts to more than ten kilowatts, while the power of large equipment can reach tens of kilowatts or even higher.

- Roller size: The roller diameter and length vary depending on the size of the equipment. For small equipment, the roller diameter may be around 100-200mm and the length may be around 200-300mm; for large equipment, the roller size is larger.

- Tablet thickness: Generally it can be adjusted within a certain range, such as 1 - 5mm, the specific range depends on the equipment design.

Corn flaking multi-roller flaking machine application scenarios

It is widely used in grain processing plants, feed plants, food plants, etc. In grain processing plants, it is used for large-scale corn flake production; in feed plants, it is used to process corn flakes as livestock feed; in food plants, it is used to produce instant corn flakes and other foods.