Extrusion Puffing Machine

- Corn flake extrusion puffing machine is highly efficient and energy-saving: It uses screw extrusion to generate high temperature and high pressure to ripen and puff the corn. It does not require additional cooking equipment and can complete the processing in a shorter time, thus improving production efficiency and reducing energy consumption.

- Good product quality: The corn flake extrusion machine can fully gelatinize corn starch, denature protein, and improve the digestibility and absorption rate of corn. The flake effect is uniform, the product has a regular shape, consistent thickness, smooth surface, and crispy taste.

- High nutrient retention: During the extrusion process of the corn flaking extruder, although the temperature is high, the time is short, which can better retain the vitamins, minerals and other nutrients in the corn and reduce nutrient loss.

- Corn flake extrusion machine is highly flexible: by adjusting parameters such as screw speed, barrel temperature, mold, etc., corn flake products of different shapes, sizes and flavors can be produced to meet diverse market demands.

- Corn flake extrusion machine is easy to operate: the equipment has a high degree of automation, the operation is relatively simple, easy to master, and reduces labor costs and labor intensity. At the same time, the equipment runs stably, the failure rate is low, and maintenance is convenient.

- Hygiene and safety: The extrusion process of the corn flake extruder is carried out in a closed barrel, which reduces the chance of external contamination and ensures the hygienic quality of the product. In addition, the high temperature and high pressure environment can kill the bacteria, eggs and pests in the corn, improving the safety of the product.

Working principle of corn flake extrusion machine

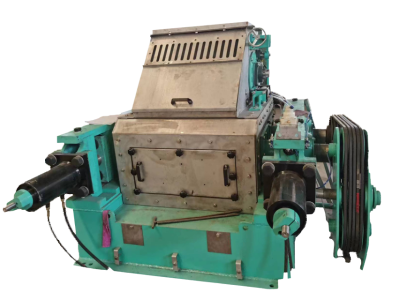

The rotation of the screw pushes the corn material forward in the barrel. In this process, the material is subjected to shear, friction, extrusion and other forces. The mechanical energy is converted into heat energy, which increases the temperature and pressure of the material, causes starch gelatinization and protein denaturation. The material is then extruded from the die, the pressure is released instantly, the volume of the material expands, and then it is pressed into corn flakes by the tableting device.

Technical Parameters

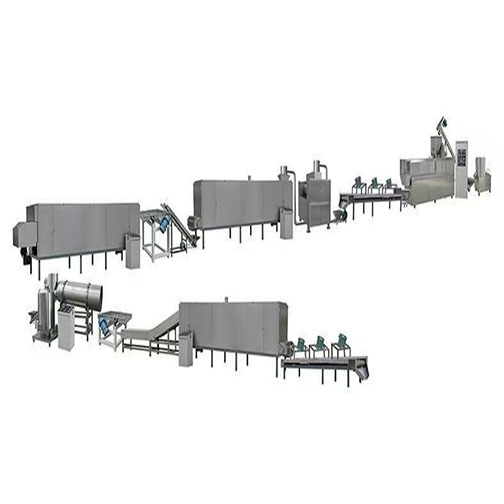

Different models of corn flake extruders have different technical parameters. For example, a certain model may have a production capacity of 120-1000 kg per hour, an installed power of 140-240 kW, an actual power consumption of 90-190 kW, and dimensions ranging from 39000mm×1200mm×2200mm to 65000mm×5000mm×4300mm.

Application scope of corn flake extrusion machine

It is mainly used for the production of corn flakes, including breakfast corn flakes, snack corn flakes, etc. It can also be used for the processing of other cereal foods using corn as raw material.

Material and structure of corn flake extrusion machine

- Material: Usually made of 304 stainless steel, which is corrosion-resistant, easy to clean, and meets food hygiene standards

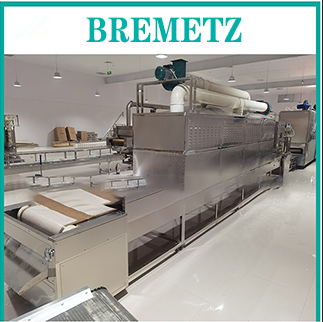

- Structure: Mainly composed of powder mixer, screw conveyor, twin-screw extruder, cooling conveyor, tablet press, oven, etc.

After-sales service of corn flake extrusion machine

Generally, manufacturers will provide a one-year warranty period, which may also include on-site installation and commissioning, operator training and other services.