Fluidized bed cooler

High cooling efficiency: The corn flake fluidized bed cooler uses airflow to fluidize the corn flakes in the bed. The corn flakes are fully in contact with the cold air, which greatly increases the heat transfer area and mass transfer efficiency. It can achieve rapid cooling in a short time and effectively improve production efficiency.

Uniform cooling: The airflow of the corn flake fluidized bed cooler is evenly distributed in the fluidized bed, so that the corn flakes can be evenly cooled in the entire bed, avoiding local overheating or overcooling, and the product quality is highly stable.

Good drying effect: During the cooling process of the corn flake fluidized bed cooler, hot air passes through the fluidized corn flake layer, which can take away a large amount of moisture and play a good drying role, helping to reduce the moisture content of the corn flakes and extend their storage period.

Strong flexibility: The corn flake fluidized bed cooler can flexibly adapt to the cooling needs of different production scales and corn flake varieties by adjusting parameters such as air flow velocity, temperature and bed height, and has strong versatility and adaptability.

Compact equipment: The corn flake fluidized bed cooler has a relatively compact structure and occupies a small area, which can effectively save production space, facilitate installation and maintenance, and also reduce equipment investment costs.

High degree of automation: The corn flake fluidized bed cooler is easy to realize automatic control and can be linked with other production equipment to realize the automatic operation of the entire production process, reduce manual intervention, and improve the stability and reliability of production.

Little material damage: The corn flakes in the fluidized bed cooler move in a fluidized state, with little collision and friction between each other and with the wall of the equipment, which can effectively reduce the breakage and damage of the material and maintain the integrity and appearance quality of the product.

How it works

Cold air enters from the bottom of the corn flake fluidized bed cooler, is evenly distributed through the air distribution plate, and then passes through the corn flake layer upward, making the corn flakes in a fluidized state. In this process, the cold air fully contacts the corn flakes, performs heat exchange, and takes away the heat of the corn flakes, thereby achieving cooling. At the same time, some moisture will be discharged with the hot air, which plays a certain drying role.

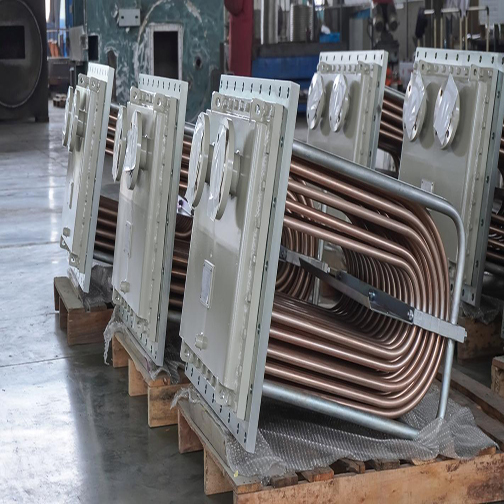

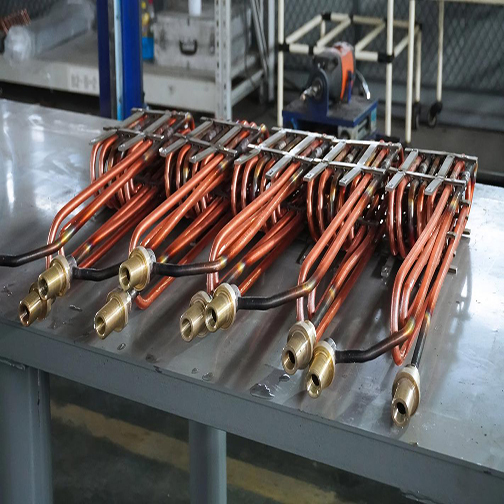

Corn flake fluidized bed cooler structure

- Air distribution system: including air inlet, air distribution plate, etc., to ensure that cold air enters the fluidized bed evenly, so that the corn flakes are evenly fluidized.

- Fluidized bed: It is the main place for cooling corn flakes. It is usually made of stainless steel and other materials with good wear resistance and corrosion resistance.

- Corn flake fluidized bed cooler distribution device: evenly distributes corn flakes on the bed surface of the fluidized bed to ensure that the material is evenly heated during the cooling process.

- Discharge device: located at the bottom of the cooler, used to discharge the cooled corn flakes. Different discharge methods can be selected according to needs, such as flap valve, spiral discharger, etc.

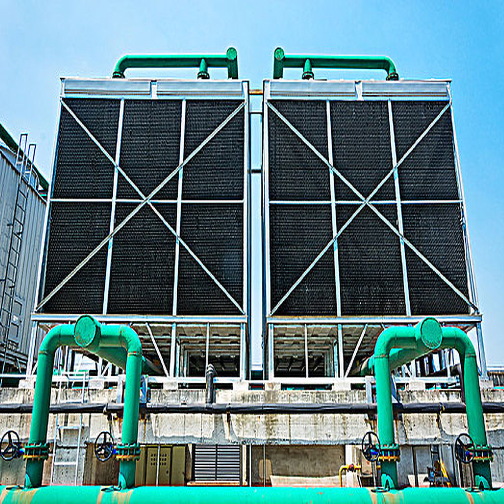

- Ventilation system: It consists of fans, air ducts, etc., to provide sufficient cool air for the cooling process and discharge hot and humid air.

Corn flake fluidized bed cooler performance parameters

- Processing capacity: Depending on the model and specifications of the equipment, the processing capacity generally ranges from a few tons to dozens of tons per hour.

- Cooling efficiency: It can reduce the temperature of corn flakes to close to room temperature in a relatively short time. Generally, it can cool corn flakes from a higher temperature to about 3℃ - 6℃ higher than room temperature.

- Moisture reduction: The moisture content of corn flakes can be reduced by about 2%-5%. The specific reduction depends on factors such as cooling time and air humidity.

Corn flake fluidized bed cooler application areas

It is mainly used in the production process of corn flakes to cool and dry corn flakes after steam flaking. In addition, it can also be used for cooling and drying other granular materials, such as wheat flakes, sorghum flakes, etc.