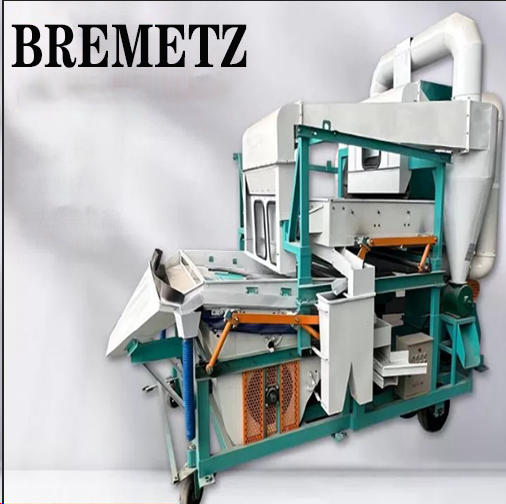

Specific gravity screening machine

- Accurate screening: The corn flake specific gravity screening machine uses the difference in specific gravity between materials and impurities for screening. It can accurately separate impurities with different specific gravity from corn flakes, such as stones, soil blocks, metals, etc., effectively improving the purity and quality of corn flakes.

- Non-destructive screening: During the screening process, the corn flake specific gravity screening machine mainly uses airflow and vibration to stratify the materials, which causes minimal damage to the corn flakes. It can better maintain the complete shape and quality of the corn flakes and avoid breakage and loss of nutrients caused by screening.

- Strong adaptability: The corn flake specific gravity screening machine can adapt to the screening needs of corn flakes of different varieties, humidity and particle sizes by adjusting parameters such as airflow size and vibration frequency. It can also handle materials with different impurity contents and has a wide range of applications.

- High efficiency and energy saving: The corn flake specific gravity screening machine has a strong processing capacity and can operate continuously and stably. It can process several tons or even tens of tons of corn flakes per hour. While ensuring the screening effect, the energy consumption is relatively low, and it has high production efficiency and economic benefits.

- High degree of automation: Corn flake specific gravity screening machines are usually equipped with automated control systems, which can realize automated operations in feeding, screening, discharging and other links, reduce manual intervention, reduce labor intensity, improve production stability and consistency, and also facilitate production management and quality control.

Working principle of corn tablet specific gravity screening machine

Positive pressure is used to produce a comprehensive effect on the material through airflow and vibration friction. Corn flakes with a larger specific gravity settle to the bottom layer and move upwards under the vibration friction of the screen surface; impurities with a smaller specific gravity, such as moldy and rotten grains, worm-eaten grains, etc., are suspended on the surface of the material layer and flow downwards under the action of airflow, thus achieving separation by specific gravity.

Corn flake specific gravity screening machine structure

It is usually composed of a frame, a transmission part, a main fan, a gravity separation table, a suction fan, a suction duct, a screen box, etc. Some models are also equipped with a bulk material collector, a dust collection device, etc. Some equipment is equipped with a steering wheel electric travel device and standard automobile wear-resistant pneumatic tires for easy movement.

Corn flake specific gravity screening machine performance characteristics

- Good impurity removal effect: It can effectively remove various impurities in corn flakes, such as moldy and rotten kernels, insect-eaten kernels, smut kernels, etc. The removal rate of moldy kernels can reach 99.9%.

- High precision: It adopts the design of double specific gravity table, integrating negative pressure specific gravity and positive pressure specific gravity functions. The material is re-sorted twice, making the impurity removal effect more excellent.

- Large output: Large equipment can reach 40-50 tons/hour for the primary processing of raw grains such as corn, and 20-30 tons/hour for the selective processing of removing moldy grains.

- Environmental protection and energy saving: Fully enclosed structure, equipped with suction hood and dust collector, can effectively collect dust; fans are connected in series to reduce wind energy loss and power consumption.

- Reliable stability: The core force points of the gravity table adopt advanced technology. The upper and lower gravity tables vibrate in opposite directions, and the inertial forces offset each other, making the equipment run more stably.

Corn flake specific gravity screening machine application range

It is widely used in the cleaning and processing of corn, wheat, rice, soybean and other crop seeds and grass seeds. It is also suitable for the screening of corn flakes. The screen mesh can be changed according to the particle size of the material.