Multi-layer drying line

- The multi-layer drying line for corn flakes makes efficient use of space: the multi-layer structure design increases the drying area in a limited space, can handle more corn flakes, improve production efficiency, and is suitable for large-scale production.

- The multi-layer drying line for corn flakes has good drying uniformity: the multi-layer design enables the corn flakes to be evenly heated during the drying process, and the hot air circulates evenly between the layers, reducing the temperature difference during the drying process, thereby ensuring the consistency of the drying quality of the corn flakes.

- The multi-layer drying line for corn flakes has high flexibility: the drying temperature, wind speed and drying time of each layer can be flexibly adjusted according to different corn flake varieties, humidity and drying requirements to achieve the best drying effect.

- Significant energy-saving effect: the multi-layer drying line for corn flakes is usually equipped with an efficient hot air circulation system, and the hot air is circulated between the layers, which reduces heat loss, reduces energy consumption, and saves drying costs.

- The multi-layer drying line for corn flakes has a high degree of automation: it is generally equipped with an automated control system, which can realize full-process monitoring and automatic adjustment of the drying process, reduce manual intervention, improve production stability and reliability, and also reduce labor costs.

How it works

The corn flake multi-layer drying line uses hot air as a drying medium to contact and move with wet materials, so that the moisture contained in the wet materials can be diffused, vaporized and evaporated to achieve the purpose of drying. The corn flakes are evenly spread on the mesh belt and are dragged back and forth in the dryer by the transmission device. The hot air flows through the materials and the water vapor is discharged from the moisture removal holes.

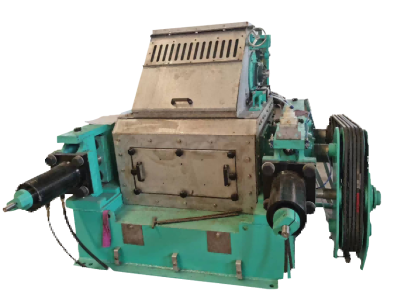

Structural features of corn flake multi-layer drying line

- Multi-layer mesh belt design: usually composed of 2-5 layers of mesh belt, the most common ones are two-chamber three-layer, two-chamber five-layer, etc., which effectively increases the drying area and improves production efficiency.

- Circulating air system: Equipped with an efficient circulating air system to circulate hot air between floors, reducing heat loss and improving thermal efficiency.

- Dehumidification system: A special dehumidification device is equipped to discharge the water vapor generated during the drying process in time to ensure the drying effect.

- Various heating methods: electric heating, steam heating, hot air heating, etc. can be used to meet the needs of different users.

- Automatic control system: Equipped with an automatic control system, it can achieve precise control of parameters such as drying temperature, wind speed, mesh belt speed, etc., to ensure the stability of drying quality.

Technical parameters of corn flake multi-layer drying line

- Drying section length: generally 6 - 40m, can be selected according to production needs.

- Thickness of the material: usually between 10 - 80mm, adjusted according to the characteristics of the corn flakes and drying requirements.

- Operating temperature: generally 50 - 140℃, different corn flake varieties and humidity may require different drying temperatures.

- Steam consumption of corn flake multi-layer drying line: depending on the equipment model and drying requirements, the steam consumption is between 360 - 1350kg/h.

- Heat exchange area: ranging from several hundred square meters to more than one thousand square meters to meet different drying needs

- Drying intensity: 150 - 900kg of moisture can be dried per hour.

- Total power of external unit: between 35.3 - 72.5KW.

Corn flake multi-layer drying line application range

It is suitable for drying flaky, strip-shaped and granular materials such as corn flakes, cereal chips, snack foods and feed.