Pressure air conveyor

Efficient transportation: The corn flake compression air conveyor uses the positive pressure airflow generated by the fan to quickly transport corn flakes to a longer distance and can achieve continuous transportation, greatly improving production efficiency.

Protect materials: The air conveying process of the corn flake compression air conveyor is relatively gentle, causing little damage to the corn flakes. It can better maintain the complete shape and quality of the corn flakes and reduce the generation of breakage and powder.

Clean and environmentally friendly: The entire conveying process of the corn tablet press air conveyor is carried out in a closed pipeline, which can effectively prevent dust leakage, avoid dust pollution to the working environment, and improve the sanitary conditions of the workshop.

Flexible layout: The conveying pipeline of the corn flake compression air conveyor can be flexibly laid according to the actual layout of the workshop, can adapt to different spatial structures and production processes, and can realize horizontal, inclined or vertical transportation without being restricted by terrain and space.

High degree of automation: The corn flake press can be linked with other production equipment for control, which makes it easy to realize automatic operation, reduce manual intervention, reduce labor intensity, and improve production stability and reliability.

Low maintenance cost: The structure of the corn tablet press air conveyor is relatively simple, without complicated transmission parts and fewer wearing parts. Daily maintenance is relatively easy and the maintenance cost is low.

Strong material adaptability: In addition to corn flakes, the corn flake compression air conveyor also has a good conveying effect on other similar flaky and granular materials. It has strong versatility and can meet the conveying needs of different materials.

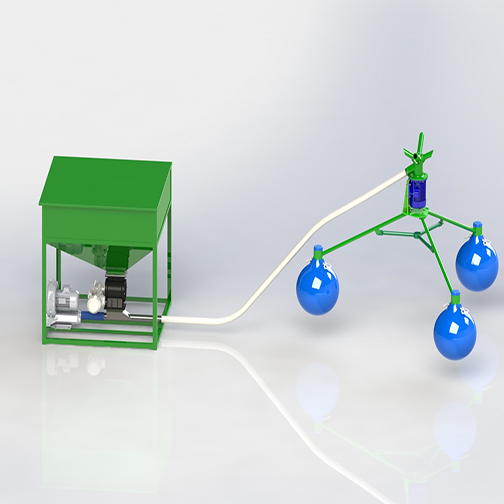

Working principle of corn flake press air conveyor

The fan generates positive pressure airflow to press the corn flakes from the feeding port into the conveying pipeline. Under the action of the airflow, the corn flakes flow along the pipeline in a suspended or grouped state and are transported to the designated location.

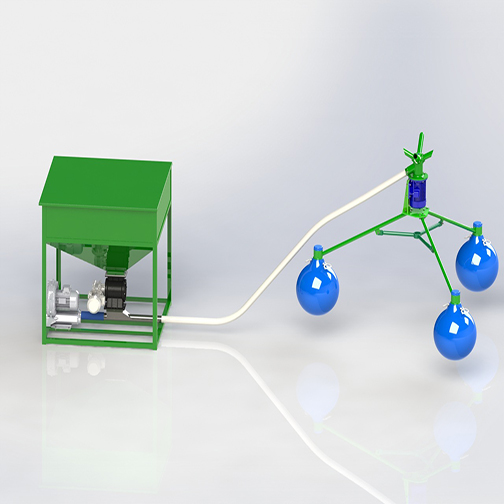

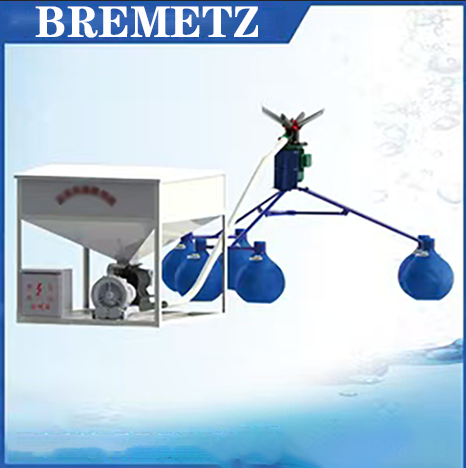

Corn flake press air conveyor structure

- Feeding device: includes hopper and feeder, ensuring corn flakes can enter the conveying pipeline evenly and stably.

- Fan: As a power source, a centrifugal fan is usually used to provide a large volume and high pressure compressed air flow.

- Conveying pipeline: Corn flake press air conveyor is generally made of wear-resistant metal or plastic, and can be flexibly arranged according to the actual conveying route to achieve horizontal, inclined or vertical conveying.

- Discharging device: At the end of the conveying process, the corn flakes are separated from the air flow and discharged using cyclone separators, discharge valves and other devices.

Corn flake press air conveyor performance parameters

- Conveying capacity: Varies depending on the equipment model, generally ranging from several tons to tens of tons per hour. For example, small equipment may convey 1-5 tons per hour, and large equipment can reach 10-30 tons or even more.

- Conveying distance: The horizontal conveying distance can reach hundreds of meters, and the lifting height can reach tens of meters. The common horizontal conveying distance is 100-300 meters, and the lifting height is 10-40 meters.

- Air source pressure: The air source pressure provided by the fan is usually between several kilopascals and tens of kilopascals to meet the requirements of different conveying distances and material characteristics.