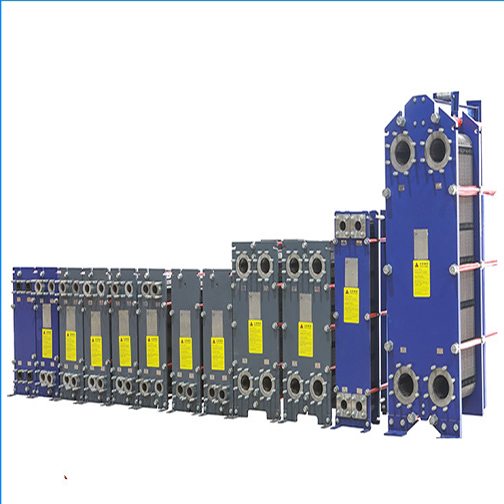

Plate cooler

Corn flake plate cooler with efficient heat transfer: It is composed of many corrugated metal plates stacked together, and thin and tortuous channels are formed between the plates, so that the corn flakes and the cooling medium can achieve sufficient heat exchange in a smaller space. The corrugated structure increases the disturbance of the fluid, improves the heat transfer coefficient, and has a higher cooling efficiency.

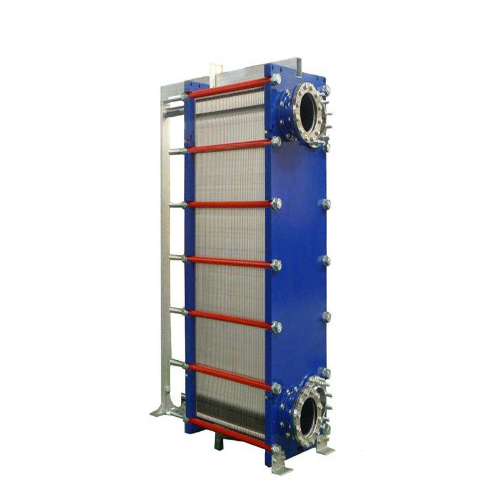

Compact structure: The corn flake plate cooler occupies a small area and has high space utilization. It is easy to install in a production workshop with limited space, which can effectively save factory space.

Flexible and changeable: The corn flake plate cooler can easily adjust the heat exchange area of the cooler by increasing or decreasing the number of plates to adapt to changes in different production scales and corn flake cooling needs.

Easy to maintain: The plates of the corn flaked plate cooler are removable, which is convenient for cleaning and checking the internal channels. Dirt and impurities can be removed in time to ensure the cooling effect. During maintenance, damaged plates can be replaced separately, reducing maintenance costs.

Good sealing: The corn flake plate cooler uses sealing gaskets or welding to connect the plates, which can effectively prevent the leakage of corn flakes and cooling medium, and ensure the stability and safety of the cooling process.

Corrosion resistance: The corn flake plate cooler can use stainless steel, titanium alloy and other corrosion-resistant materials to manufacture the plates, which can adapt to the cooling media of different properties and the characteristics of corn flakes, and extend the service life of the equipment.

Energy saving and consumption reduction: Due to the high heat transfer efficiency of the corn flake plate cooler, when achieving the same cooling effect, the required cooling medium flow and power consumption may be lower than some other coolers, which is conducive to saving energy and reducing production costs.

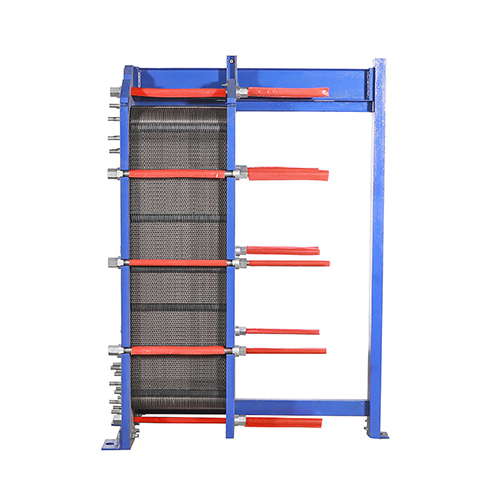

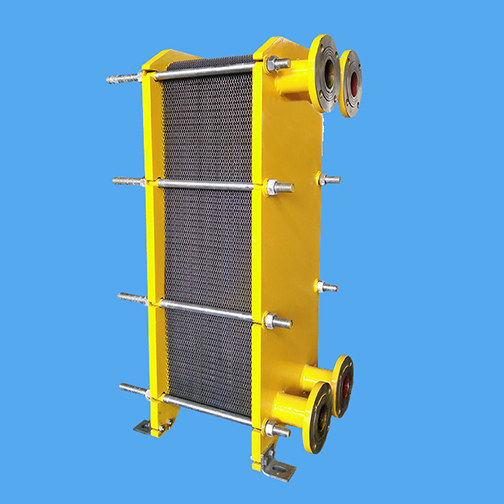

Corn flake plate cooler structure design

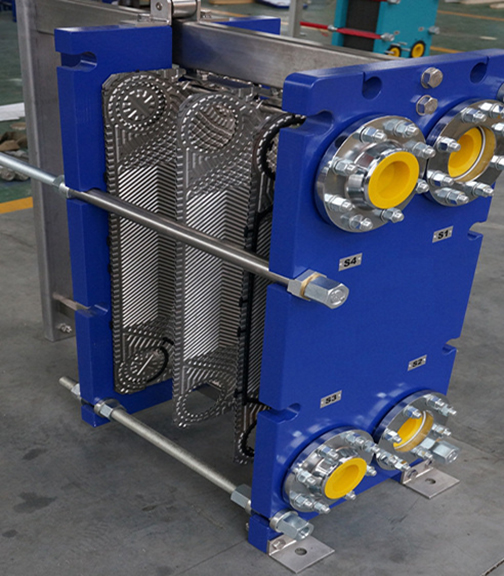

- Plate: Made of corrosion-resistant metal materials such as stainless steel, the thickness is generally 0.4-0.8mm, and the surface is stamped into corrugated shapes, such as herringbone, horizontal straight corrugation or nodular shape, which can increase fluid disturbance and improve heat transfer efficiency.

- Sealing gasket: Sealing gaskets made of rubber and other materials are used around the plate and at the corner holes to prevent leakage of corn flakes and cooling medium.

- Frame: It includes fixed clamping plates, movable clamping plates, upper and lower guide rods and clamping bolts, etc., which are used to fix and clamp the plates to form a compact structure.

Working principle of corn flake plate cooler

Corn flakes and cooling medium flow in the channels between adjacent plates respectively, and heat is exchanged through the plates to achieve cooling of corn flakes. Parallel or countercurrent flow is mostly adopted, with high logarithmic mean temperature difference correction coefficient, small terminal temperature difference and good cooling effect.

Corn flake plate cooler performance parameters

- Heat transfer coefficient: Generally 3-5 times that of shell and tube coolers. Under the same flow resistance and pump power consumption, it can transfer heat more efficiently and achieve rapid cooling.

- Pressure loss: Due to the narrow channel between the plates and the corrugated structure, the pressure loss per unit length is greater than that of the traditional smooth tube cooler, but by reasonably designing the flow rate and channel layout, the pressure loss can be controlled within a reasonable range.

- Processing capacity: According to the production scale and demand, by selecting different plate numbers, sizes and arrangements, the heat exchange area and processing capacity of the cooler can be flexibly adjusted to meet the cooling needs of corn flakes with different outputs.

Material selection for corn tablet plate cooler

- Plate material: Stainless steel, such as 304, 316L, etc., is usually used, which has good corrosion resistance, strength and thermal conductivity; for special working conditions, more advanced materials such as titanium alloy can also be used.

- Sealing gasket material: Common ones include nitrile rubber, EPDM rubber, etc., which have good elasticity, sealing and chemical corrosion resistance, and can adapt to different cooling media and working temperature ranges.

Corn flake plate cooler application scenarios

It is mainly used in the cooling process of corn flake production, which can quickly cool the high-temperature corn flakes after steam flake or drying to a suitable temperature, which is convenient for subsequent packaging, storage and transportation. It can also be used for other similar cooling processes in grain processing or food production.