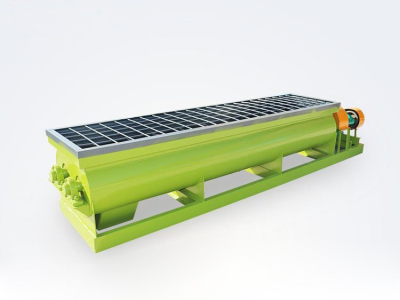

Mesh belt multi-layer oven

- Corn flake mesh belt multi-layer oven for efficient continuous production: The mesh belt design allows the corn flakes to move continuously in the oven, achieving automated continuous production, greatly improving production efficiency and being suitable for large-scale industrial production. The multi-layer structure increases the baking area and can process a large number of corn flakes at the same time, further improving production capacity.

- Uniform heating: Equipped with a circulating fan and a reasonable air duct design, the hot air is evenly distributed in the oven. The corn flakes move at a constant speed on the mesh belt and can be fully and evenly heated. The baked product has a consistent color and taste, ensuring the stability of product quality.

- High product quality: The corn flake mesh belt multi-layer oven provides sufficient baking time and space for corn flakes, so that they can be fully dehydrated and cooked, better forming a unique flavor and taste, and improving the quality of corn flakes.

- Flexible process: The corn flake mesh belt multi-layer oven can flexibly adjust parameters such as mesh belt speed, oven temperature and baking time according to different corn flake varieties, thickness and baking requirements to meet diverse production process requirements.

- Easy to clean: The mesh belt is made of stainless steel with a smooth surface, which is not easy to adhere to corn flakes crumbs. It is easy to disassemble and clean, in line with food hygiene standards, can effectively avoid cross contamination and ensure product quality and safety.

- Long service life: The overall structure of the corn flake mesh belt multi-layer oven equipment is solid, and the key components are made of high-quality materials. The mesh belt has high strength and wear resistance, the heating system is stable and reliable, and the maintenance is simple. Therefore, it has a long service life and can reduce the cost of equipment use.

Structural design of corn flake mesh belt multi-layer oven

- Multi-layer mesh belt structure: usually 5-7 layers of mesh belt, effectively increasing the drying area, improving production efficiency and shortening the drying time.

- Circulating air system: equipped with circulating fans and reasonable air ducts to evenly distribute hot air and ensure that the corn flakes are evenly heated.

- Transmission system: generally adopts double-pitch roller chain transmission, reciprocating drying, stable operation, no jamming.

- Insulation design: The oven uses high-quality insulation materials to reduce heat loss, reduce energy consumption, and ensure a safe working environment.

Working principle of corn flake mesh belt multi-layer oven

Corn flakes are evenly placed on the multi-layer mesh belt through the automatic feeding device, and the mesh belt moves slowly under the drive system. The hot air generated by the heating system circulates in the oven under the action of the circulating fan, fully contacts the corn flakes, evaporates the moisture, and completes the drying process. The moisture is discharged from the oven through the dehumidification fan.

Corn flake mesh belt multi-layer oven heating method

- Electric heating: It has the advantages of fast heating, high efficiency and precise temperature control, and is suitable for small to medium-sized production lines.

- Steam heating: high thermal efficiency, capable of rapid heating, suitable for large-scale production, can ensure that the product is dried at a low temperature to reduce the loss of nutrients.

- Oil and gas heating: can provide continuous and stable high temperature, high thermal efficiency, suitable for large production lines and long-term continuous working environment.

Corn flake mesh belt multi-layer oven control system

- Temperature control: Equipped with a thermostat, the temperature of each layer in the oven can be accurately controlled. The temperature control range is generally between 0-200 degrees Celsius.

- Mesh belt speed control: The mesh belt speed is adjusted by the frequency converter, so as to flexibly adjust the drying time according to the drying requirements of corn flakes.

Corn flake mesh belt multi-layer oven materials and specifications

- Material: The whole equipment is made of stainless steel, which meets food grade safety standards, is corrosion-resistant and easy to clean.

- Specifications: The most common specifications are 5 layers and 8 meters. Equipment with different numbers of layers and lengths can also be customized according to customer needs to meet different production requirements.

Corn flake mesh belt multi-layer oven application range

It is mainly used for drying corn flakes, and can also be widely used in drying other puffed foods, grains, pet food, textured protein, etc.

Corn flake mesh belt multi-layer oven maintenance and care

The equipment maintenance is relatively simple. Regularly clean the heating components, mesh belts and dehumidification system, check the wear of transmission components, and replace wearing parts in time to ensure the long-term and stable operation of the equipment.